The Construction Industry’s Rocky Road to Recovery

We’re a little over a year and a half into the COVID-19 pandemic and the construction industry, like many other industries, is maneuvering several obstacles on its road to recovery. I think it’s important that we take time to understand what this means in the immediate and for the long-term.

![]()

Did you miss our previous article…

https://www.arizonasolarsociety.com/?p=1516

Top 10 Largest Construction Project Starts in Canada and Trend Graph – September 2021

The accompanying table records the 10 largest construction project starts in Canada in September 2021. Also included is the latest trend graph on starts. This looks at 12-month moving totals of the civil and nonresidential building categories in Canada.

![]()

Did you miss our previous article…

https://www.arizonasolarsociety.com/?p=1512

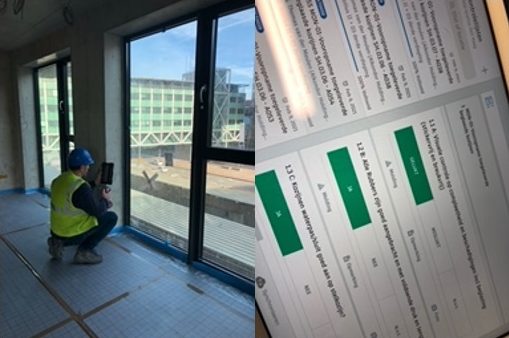

Data-Driven Insights Improving Quality With Alkondor

Based in Holland and founded in 1990, Alkondor engineers and produces façades, windows and doors, particularly for large and complex projects. The team work on a host of construction projects from residential to non-residential buildings, like hotels and cinemas, and have specialist expertise with complex architecture programmes.

Digitalising to reduce risk

With their own production facility in the Netherlands, 150 employees support Alkondor’s activity including Chris Schoneveld, BIM Manager and Bram Kotter, CEO. When Chris joined the team five years ago, his remit was to focus on all of Alkondor’s digital processes, including how the team can use digital solutions for better insights and modernise their ways of working.

At the time, the team used many time-consuming processes which included printing physical copies of PDF documents and delivering them between departments and to the factory manually. This meant that there was a layer of risk added to projects – working in such manual ways mean newer versions of drawings were again hand-delivered to production teams in the factory. “It was very easy for things to go wrong,” reflects Chris. “We were working in a way that was open for errors and meant there was a lot of work for everyone; we used Excel forms, handwritten notes, PDFs and spent a lot of time transferring and tracking documents.”

With all documents stored on local servers, soon the team recognised they began to have issues with different naming conventions on drawings and poor practices led to miscommunication and confusion. “It would be difficult to search between different documents,” says Chris. Alkondor decided that they needed to change the way they in which they managed their documents and knew that investment in their digital processes would help them be more efficient and collaborative when it came to working on their projects.

A step change in ways of working

“We were already using some digital products such as Revit,” reflects Bram. “We were working with ITANNEX (Arkance systems), an Autodesk reseller, who introduced us to Autodesk Construction Cloud’s BIM 360 platform.” Alkondor began trialling BIM 360 to see how the functionality could support the team with their document management activities as well as supporting version controlling and issues management.

To start with, Alkondor undertook a pilot project with a small group who trialled using BIM 360. The pilot group tested how the team could share documents and data from Autodesk’s Revit platform straight into BIM 360, but they also tested other functionality like quality control and issues management.

After an initial trial, Alkondor decided that they wanted to roll out BIM 360 across all of the organisation and provide dedicated training to their team to ensure this investment was firmly embedded in the company’s ways of working. Bram introduced the solution during learning sessions for all employees, with Chris taking colleagues through the features and functionality. Chris also ensured he was available on site so the team using the solution were able to ask questions and troubleshoot collaboratively.

“I think the best features we have found in BIM 360 is the quality elements we can derive. We can document and freeze elements at certain points during construction,” says Chris. “This means we can complete extra quality checks which avoid extra costs that could be incurred to our products we install on site.”

The team use Ipads on construction sites and in the factory where they can access BIM 360. They use digital checklists for quality checks, and this also means they reduce the amount of paper used, ensuring Alkondor’s carbon footprint remains as low as possible.

Having digital document management practices means that all Alkondor team members can find documents quickly and easily using Autodesk Construction Cloud’s BIM 360 platform. “Being able to search and find documents easily saves a lot of time,” says Chris. “We can also see version history and there is a clear audit trail when it comes to changes.”

Capturing learnings for greater insights

When it comes to learnings on each project, Alkondor use BIM 360 to capture insights on the progress of their projects to provide greater certainty. Chris remarks: “We have integrated PowerBI with BIM 360 so we can visualise our data and improve outcomes. We use PowerBI and BIM 360 to provide detailed information about the project’s progress. Sometimes we adjust production and engineering processes where necessary to ensure there is no disruption to our projects.” For project managers at Alkondor, this provides them with an overview of each project helping them to make more informed decisions.

For Alkondor, quality is underpinned by their use of BIM 360. “All of our windows and doors are digital assets within the BIM 360 asset module,” says Bram. The team use this module to track the progress from their factory to project handover. “We add quality checks during the different stages of production and element mounting,” says Bram. “We can visualise our asset progress again using PowerBI dashboard updates with the help of Autodesk’s data connector. This updates every two hours and provides valuable information to our managers,” says Bram.

The team managers in the production area can review both data and issues using this functionality. This means that communication between the production and preparation departments are much more streamlined.

“Things are much quicker and time isn’t lost waiting on information,” – Chris Schoneveld, BIM Manager, Alkondor

“For example, colleagues in the production areas can attach issues to drawings to ensure the right materials are being ordered. This can all happen in BIM 360 with ease.”

This also means the teams have much more insight into what is going wrong and what can be done to change it. When it comes to Alkondor’s use of BIM 360, the company are embedding its use more and more. The team have used BIM 360 on 197 projects, documented 13810 issues and created 17500 checklists as well as 10500 assets.

Data, data and more data

For Alkondor, having meaningful data available to analyse is significant. Chris reflects: “We have data and dashboards to make it immediately visible. Previously, we couldn’t analyse anything, but now we can use BIM 360 to analyse everything.” When it comes to using this data, it is invaluable to be able to document and capture the quality of products at a moment in time. “In the past, we were unable to confirm with our clients that there weren’t any scratches on door panes, broken glass or concrete stripes. So if there was a defect afterwards, customers could blame us and ask to front the costs for solving it,” says Chris. Now, Alkondor has evidence of the quality of their outputs on a set date. Which is stored in BIM 360. Depending on the project, that could save somewhere between 10,000 euros to 100,000 euros.

In the future, the team is looking to add in sensor data, so that the business can offer services like predictive maintenance. As an example, they could use this functionality to identify that one door opens once a year, while another opens a thousand times a year. They could use that data to inform predictive maintenance schedules.

For Alkondor, embracing technology of the future like the use of robotics in their factories means they will enable their workforce to focus on higher value and complex work. Being able to offer data to their customers also means that they can be more transparent and provide information that will help their customer to better manage the asset in the future.

“We are committed to embracing technology today so that we can use it for the better in the future,” says Bram. “This also means we can be more flexible as a company – for example pivoting our market offering from projects to ongoing services which will provide us with more revenue streams to explore. And at the heart of all of this for Alkondor is using their data for the better.

The post Data-Driven Insights Improving Quality With Alkondor appeared first on Digital Builder.

Did you miss our previous article…

https://www.arizonasolarsociety.com/?p=1507

How Clash Detection Evolved Into Everyone’s Tool

Teams are changing their approach to collaborative design

Over the last several years, we’ve seen a major shift in the ways project teams work together and the requirements that owners put on contractors. Design-Build project delivery, lean methodologies, and joint ventures are at an all-time high, and accelerated by digital adoption from at-home work and the Covid-19 pandemic. In fact, 58% of owners said they’ve used or plan to use design-build, moving away from traditional design-bid-build (FMI).

This could be, in large part, because design-build projects are completed 102% faster than traditional design-bid-build (DBIA). As construction teams move towards an integrated approach, organizations from Architecture-Engineering firms to contractors and trades will need to adapt their processes and adopt standard ways of working to better communicate and coordinate in dynamic environments.

Do the benefits of tech-driven collaboration outweigh the risks?

The fundamentals of construction haven’t changed much over time. Schedule constraints, geometry conflicts, sequencing, safety, and quality will continue to challenge project teams and require the very best from problem-solvers in every organization. Firms that react to industry changes will improve on these fundamentals—helping them to save on unnecessary costs and capture back some time back in their day. Better collaboration across the project lifecycle will pad schedule margins, focus teams on delivering up-front quality, and provide leaders with the provable success history to win the right kind of work for their firm.

As competition for new work increases and governments apply more standards to the construction industry, firms must innovate or risk losing out on the right kind of projects for their portfolio. The challenge comes with “how” firms adapt and what paths they take to improve their delivery metrics. It can’t be enough to purchase the newest technology and call it a day. The real work comes with getting buy-in from project partners and unlocking the contributions from the entire team, from architects and BIM managers to subcontractors. This is especially important in the coordination process.

How clash management has been done historically

Today, much of the pre-coordination meeting work rests on the shoulders of a BIM manager. Models need to be sorted, uploaded, and aggregated. Navisworks is often a tool of choice to navigate models, check for clashes, and assign issues with views. Weekly coordination meetings pull together the shared expertise of the entire project team to assess issues and work together to troubleshoot and resolve issues generated by the BIM manager.

Oftentimes, however, these meetings focus too much on low priority issues—aligning models, resolving simple clashes among teams, and making sure previous decisions were executed correctly. Slow coordination among teams compresses the overall schedule, making clash resolved models more of a luxury in some cases.

Navisworks is one of the most trusted and powerful tools for refining models. Those who know it love it. And there are no indications this level of clash granularity is ever going away. But to keep up with moving deadlines and changing design elements, project teams need to find a hybrid approach to clash management; one where engineers, architects, and trades are taking part in a simplified and continuous model coordination process while the BIM Manager uses their expertise to focus on high value issues.

Clash management is now for everyone, not just BIM managers

It’s not enough to throw a fresh coat of paint on the old way of managing clashes and repackage clash detection for BIM managers. A shift in mindset needs to occur that gets the whole team engaged in clash detection. Fundamentally, teams need to be collaborating throughout the week to identify, resolve, and even prevent issues from the earliest stages of a project. The value in doing so, is a better reputation for quality and timely work, less time spent on non-optimal activities, and more time spent on solving problems before they hit the field.

Clash detection must be simple enough for anyone to use it.

Clash detection then, must be simple enough for anyone to use it. It needs to automate repetitive tasks, reduce the set-up time to near zero, and work in-conjunction with the tools people use every day.

Autodesk BIM Collaborate does just that. Anyone on the project team can set up a coordination space in a common data environment, and when files are added or updated there, they are automatically clashed against the other models. Clashes are automatically grouped by object, property, system name, or type name, giving the clash novice or seasoned expert easy ways to locate types of clashes for clearing. A clash tolerance filter dynamically changes the clash list, reducing the noise and focusing individual users only on larger clashes. Clashes are arranged in a matrix so everyone is aware of the problem areas and BIM managers can focus on specific disciplines or floors.

More on the technical side, project stakeholders using third-party authoring applications for design who also want to see their files aggregated and clashed, can see their work in a multi-model context with intermediary file types like NWC or IFC. These files can be aggregated and clashed alongside RVT and DWG files.

Once a clash has been identified as an issue, it is automatically shared across the entire issue eco-system. If a design lead identifies an issue in BIM Collaborate, BIM managers in Navisworks and engineers in Revit can pick up that issue in either of those tools. The assigned issue is then tracked in each of the products, desktop or web based, throughout the system.

This allows teams to communicate about issues in the tools they use day-to-day. And with a direct link to the web from desktop applications like Revit, design teams can get a quick health check on their work in a multi-model context.

Navisworks users who need to investigate issues to determine next steps can see the highlighted clashes in context to fully understand it. If there’s any ambiguity, they can comment on an issue, which is then available in Revit, other Navisworks applications, Autodesk Docs, Autodesk Build, and Autodesk BIM Collaborate.

Better business for all

With this level of connectivity, multidisciplinary teams can now communicate early and often in one place, using a common data environment as a single source for project files. Removing the barriers between teams and allowing multiple stakeholders to clear clashes improves design quality and the speed of work done in preconstruction phases. When coordination timelines compress, and they often do, it’s important to have more eyes on the constructability of a project to ensure the quality owners expect and field partners need.

Being adaptable means having the right tools for the right job. And in a world where immediate access to data is a necessary component to achieving positive project outcomes, teams need their tools to connect to a common data environment. When authoring tools, powerful clash tools, simple clash tools, and issues are all connected in one place, the difficulties of a fast-moving design-build project are no longer technological. Organizations can prove their ability to act with innovation and can build a reputation as being collaborative and predictably successful.

If you’d like to learn more about Autodesk BIM Collaborate and what it can do for your business specifically, please contact us for a demo. We’d love to show you around.

The post How Clash Detection Evolved Into Everyone’s Tool appeared first on Digital Builder.

Did you miss our previous article…

https://www.arizonasolarsociety.com/?p=1496

U.S. Foreign Trade Position is Worsening; Canada’s is Healing

Record ‘Goods’ Trade Deficit & Deterioration in ‘Services’ Surplus

In discussions about gross domestic product (GDP), foreign trade receives the attention it deserves in Canada, but it’s undervalued in the United States. The reason undoubtedly has to do with the shares of GDP contributed by exports in the two countries.

![]()

Did you miss our previous article…

https://www.arizonasolarsociety.com/?p=1492

Gap Between Bid Price Increases and Material Cost Increases Is Narrowing

In the spring and summer of this year, a huge gap opened between construction bid prices that were staying low on a year-over-year basis and material input costs, also y/y, that were soaring into the stratosphere.

![]()

Did you miss our previous article…

https://www.arizonasolarsociety.com/?p=1488

5 Steps for Preventing Construction Site Theft

From building materials to tools to heavy equipment, construction site theft is an industry-wide epidemic. In addition to the direct costs of replacing the stolen goods, there is also the indirect cost due to increased insurance premiums, rental costs to replace stolen equipment, and lost productivity.

![]()

Did you miss our previous article…

https://www.arizonasolarsociety.com/?p=1484

5 Must-Hear Construction Podcast Episodes from 2021

Jobsites aren’t the only loud places in construction; the ecosystem of construction technology produces a lot of noise too. It can be difficult to cut through what’s real, what’s hype, and what can actually help you improve how your team gets their work done. That’s partly why we decided to launch Autodesk’s Digital Builder podcast and share stories from ambitious leaders from across the construction industry.

On our podcast, we get into the corners of what works, what doesn’t, and what the future for the industry holds. To wrap up the year, I wanted to look back (in no particular order) at a few particularly interesting episodes from 2021.

Episode 17: Diving Deep on Communication & Collaboration in Construction w/ Eddie & Tyler Campbell

Working across upwards of twenty companies during a project is typical in the AEC industry. Each company usually has multiple people involved as stakeholders, each with their own prescriptions and priorities. The only way for a project to run smoothly is to prioritize communication and collaboration. For the best project outcomes, everyone must be on the same page.

Eddie Campbell, COO at ABSI (Accelerated Building Solutions, Inc.) and Tyler Campbell, Vice President, also at ABSI, are no strangers to the highs and lows of construction collaboration. The co-hosts of the Construction Brothers Podcast joined us to share best practices for increasing cooperation within projects.

You’ll learn actionable tips for:

- empowering subcontractors for better collaboration

- navigating contract disputes

- improving the bidding process

- enhancing management styles

Listen here: Apple Podcasts, Spotify, Stitcher, Google Podcasts, and anywhere else you listen.

Episode 20: Uncovering Actionable Insights from Construction Data with a Platform

Spend any time listening to thought leaders discuss construction technology and you’ll undoubtedly hear the term “platform” come up. Understanding what to expect from a construction platform is the first step to getting the most out of the technology you use. A true platform should provide a single location for designers, engineers, and builders to harness data and tools from anywhere, at any time.

In the twentieth episode of the Digital Builder podcast, you’ll hear from Jim Lynch, Senior Vice President & General Manager, and Sid Haksar, Head of Construction Strategy, both with Autodesk, on what defines a true platform and how to make sure you select the right one. Jim and Sid share their most tried and true tips for evaluating construction platforms and technology.

You’ll also discover:

- the top five considerations for evaluating construction platforms and technology

- what to expect from data and digitization in the future, and the importance of platforms in modern construction

Listen here: Apple Podcasts, Spotify, Stitcher, Google Podcasts, and anywhere else you listen.

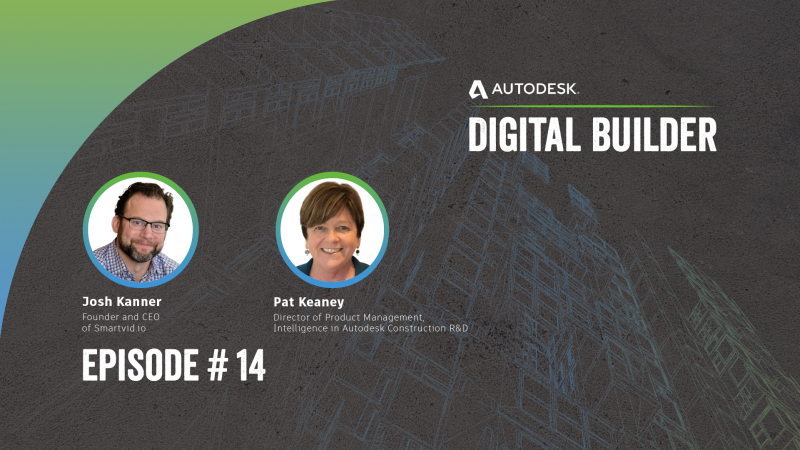

Episode 14: Demystifying Artificial Intelligence & Machine Learning in Construction: Buzzwords or Essential Tools?

What comes to mind first when you think of Artificial Intelligence (AI) and Machine Learning (ML)? It isn’t uncommon to think of super-skilled robots and a loss of human touch in the workplace. But as you’ll discover in this episode of the Digital Builder podcast, AI and ML are key to improving the safety of jobsites, the productivity of teams, and institutional knowledge for construction firms.

Here to demystify the realm of AI & ML in construction are Josh Kanner, Founder and CEO of Newmetrix (formerly Smartvid.io) and Pat Keaney, Director of Product Management, Intelligence at Autodesk Construction R&D. Josh and Pat break down the two innovative technologies in an accessible way while sharing real-world examples of their practice.

You’ll walk away with a greater understanding of:

- what machine learning and artificial intelligence really are

- how these technologies can benefit construction

- what’s next for AI and ML in the industry

- the common misconceptions about this type of technology

Listen here: Apple Podcasts, Spotify, Stitcher, Google Podcasts, and anywhere else you listen.

Episode 10: Global BIM Adoption: Where We’re At & Where We’re Going w/ Ariel Castillo & Steve Rollo

The adoption of Building Information Modeling (BIM) at an international level has as many opportunities as it does challenges. Many in the industry wonder when—if ever—we’ll reach a global standard for the process.

Ariel Castillo, Strategic Process & VDC Specialist at Miller-Davis Company, and Steve Rollo, National BIM/VDC Manager at Graham, explore these big ideas on episode 10 of the Digital Builder. As Ariel and Steve discuss the future of global BIM standardization, they’ll also share what BIM and Virtual Design & Construction (VDC) really mean. Expect to hear lots about the biggest challenges with rolling out new construction technologies as well.

Other points of conversation include:

- the state of BIM adoption and standardization in Latin America and Canada

- predictions for BIM globally over the next decade

- expectations for changing terminology

Listen here: Apple Podcasts, Spotify, Stitcher, Google Podcasts, and anywhere else you listen.

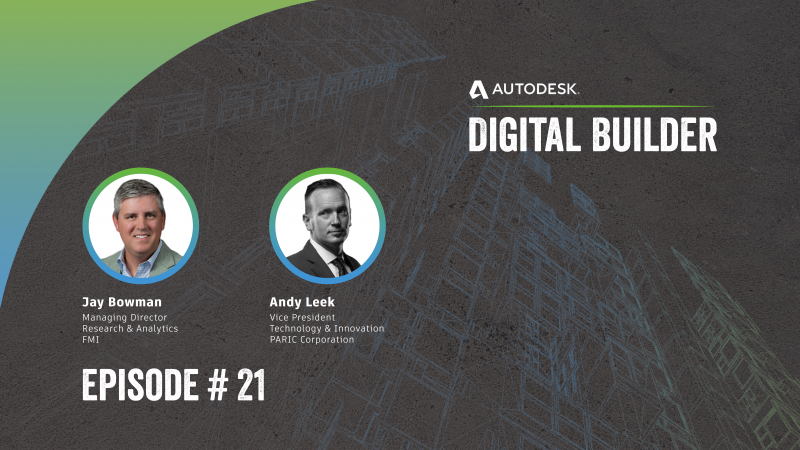

Episode 21: Data Strategy in Construction: Finding a Competitive Edge

Making better decisions in modern construction often comes down to having the right data. Leading firms have fine-tuned strategies for data management so they can rapidly harness insights and leverage more advanced technologies further down the line.

Jay Bowman, Managing Director of Research & Analytics at FMI, and Andy Leek, Vice President – Technology & Innovation at PARIC Corporation, break down the benefits of strong data strategies in the twenty-first episode of the Digital Builder. If you’ve always wondered how to get started on building a robust data strategy, you won’t want to miss their gems of wisdom.

Learn from Jay and Andy about:

- how to make sure you’re capturing useful data

- how a baseline of data strategy leads to more advanced technologies

- how to improve data literacy in construction

- the future of data in construction

Listen here: Apple Podcasts, Spotify, Stitcher, Google Podcasts, and anywhere else you listen.

Share with your team

While we’ve highlighted five popular episodes to begin your listening journey with Autodesk’s Digital Builder podcast, feel free to binge the rest on your rides to and from work or the jobsite. Each episode is carefully curated to provide insights into the modern construction industry you just won’t find anywhere else. Don’t forget to share your favorite episodes and discuss with your team. A new episode drops every two weeks and you can subscribe on:

- Apple Podcasts

- Spotify

- Stitcher

- Google Podcasts

- or wherever you listen to podcasts

The post 5 Must-Hear Construction Podcast Episodes from 2021 appeared first on Digital Builder.

State of the Construction Industry: November 2021 Roundup

Much-needed good news for the construction industry highlights the stories we were following in November.

Did you miss our previous article…

https://www.arizonasolarsociety.com/?p=1474

11 Construction Jobs That Work (Much) Better with Construction Technology

New software technology is helping many parts of the construction business go faster. See 11 hotspots where the rubber hits the road!

Did you miss our previous article…

https://www.arizonasolarsociety.com/?p=1471