Home » Construction Blogs (Page 9)

Category Archives: Construction Blogs

Campaigners win court fight to block £1.7bn Stonehenge tunnel

Campaigners have won a court battle to block the £1.7bn construction of a road tunnel near Stonehenge.

Mr Justice Holgate has ruled that a decision to allow a dual carriage way road and tunnel to be built within the ancient World Heritage Site was unlawful.

The judgment effectively quashes development consent for the A303 improvement project which was granted by Transport Secretary Grant Shapps.

Shapps will now have to decide whether to appeal against the judge’s ruling that he had not properly assessed the risk of harm to the World Heritage Site

The judge further concluded that Shapps had made an error of law by failing to consider alternatives to the scheme, such as a longer tunnel, which may have been less damaging to the Stonehenge.

Highways England said: “We now have to wait while the Department for Transport considers its options.

“This is a setback, but we remain confident our project is the best solution to the ongoing issues along the A303 past Stonehenge and was developed after a long and extensive collaboration with our key stakeholders.

“We are hugely disappointed by the decision, and we know this will also dismay many people in the local community who have waited decades for a solution and all those who use the road to travel to work or on holiday in the south west.”

John Adams, Acting Chairman of the Stonehenge Alliance, said: “We could not be more pleased about the outcome of the legal challenge.

“The Stonehenge Alliance has campaigned from the start for a longer tunnel if a tunnel should be considered necessary. Ideally, such a tunnel would begin and end outside the WHS.

“But now that we are facing a climate emergency, it is all the more important that this ruling should be a wake-up call for the Government. It should look again at its roads programme and take action to reduce road traffic and eliminate any need to build new and wider roads that threaten the environment as well as our cultural heritage.”

Leigh Day solicitor Rowan Smith said: “This is a huge victory, which means, for now, Stonehenge is safe.

“The judgment is a clear vindication of our client’s tremendous efforts in campaigning to protect the World Heritage Site.

“The development consent for this damaging tunnel has been declared unlawful and is now quashed, and the Government will have to go back to the drawing board before a new decision can be made. Meanwhile, one of the country’s most cherished heritage assets cannot be harmed.”

Did you miss our previous article…

https://www.arizonasolarsociety.com/?p=197

Guide to Construction Equipment Management: Everything You Need to Know

Construction only grows more complex each passing year, if not each quarter. As these complexities increase and timelines grow tighter, the management of resources becomes increasingly important. Equipment makes up some of the most valuable assets in this category. These items are not only expensive to purchase but also to maintain. Studies show that the maintenance of construction equipment plays a role in about 40% of total project overrun costs.

Broken equipment has a domino effect on projects, leading to downtime, additional expenses, and frustrated owners. Putting more effort into planning the management of your equipment and its maintenance can improve project and financial outcomes.

Fortunately, prioritizing construction equipment management has proven to pay off. Today, we’ll take a look at what successful equipment management looks like and the innovations to make the management process much more efficient.

What Is Construction Equipment Management?

As you probably guessed, construction equipment management refers to the administration of equipment used on construction projects. At a more detailed level, the practice encompasses the review of the equipment, its costs, and usage.

Construction managers want to ensure that the cost of the equipment pays off in the long run. Besides the cost of the equipment itself, there are expenses associated with operation, maintenance, usage, and storage. Construction managers study this information alongside upcoming and current projects to inform decision-making. Ultimately, the goal of these decisions is to generate the highest possible ROI.

Tips for Effective Equipment Management

Your construction equipment management system will vary depending on your needs. However, here are some key tips to making your system a success::

Determine the Right Tracking Workflows

To manage construction equipment successfully, start by establishing the right tracking workflows. This information should be used to drive decisions made by project managers, professional engineers, superintendents, owners, inspectors, etc.

Basically, you need insights to determine in real time if:

- The right equipment has been delivered

- The equipment has been installed

- The equipment has been inspected

- The appropriate data has been collected

With the right tracking workflows in place, this information can also be harnessed for more efficient handover and operations.

Set Up a Preventative Maintenance Program

Next, prioritize maintenance. Preventative maintenance is essential to extending the life of your equipment and avoiding costly repairs. As MacAllister puts it, “Preventive maintenance is more than regular maintenance like lubricating moving parts and changing filters. A proper preventive maintenance (PM) program is all-inclusive. It’s an intentional approach to equipment management from the time equipment is purchased until the end of its useful life.”

PM programs take action before wear and tear lead to major expenses or equipment failure. Through regular inspections, part replacement, testing, and analysis, you can improve the reliability, performance, and resale value of your fleet.

Create Collaborative Communications Plans for Equipment

Your frontline workers are the ones most likely to identify issues with equipment or delivery. For optimal usage, your team needs to be notified when equipment is on-site, on its way, or if any changes take place. By creating a collaborative communications plan, this information can get in the right hands at the right time.

The benefits of this type of plan for construction equipment management include:

- Proactively addressing damages, repairs, and delays

- Preventing people from using inoperable or damaged equipment

- Facilitating ordering of parts

Be sure to integrate cloud-based construction technology into your communications plan; that way, you can collaborate with stakeholders in real time and have a single source of information.

Monitor Your Equipment Smartly

Managing a fleet can make it difficult to know where your equipment is at all times. The same is true for scheduling maintenance across multiple items. IoT sensors can help to reduce the manual nature of monitoring equipment and planning maintenance.

According to Leverege, construction equipment managers can leverage IoT technology to:

- Track equipment status and utilization

- Identify the location and status of equipment in real time

- Get instant notifications when equipment is moved off-site

- Monitor engine runtime

Benefits of Successful Construction Equipment Management

Setting up an equipment management system takes time. You might be wondering, “Is it really worth the effort?”

The answer, of course, depends on the benefits received by the system. You can expect to achieve the following advantages from successful equipment management:

- Better visibility into where equipment is located, its status, and how it’s being used.

- Fewer delays and cost overruns. With real-time information at their fingertips, teams can make quick decisions about how to use equipment.

- Better safety standards as the equipment is kept up-to-date and maintained.

- Less downtime as equipment can be used as soon as it’s available.

- Reduced expenses in the form of costly repairs and project overtime.

- Cohesive data to help inform decisions about retiring, selling, or upgrading assets.

The Top Technology for Construction Equipment Management

As managers look for ways to improve the efficiency of their construction equipment, new innovations are coming to the forefront. Here are some solutions to keep in mind while building your system:

Intelliwave: With their SiteSense platform, you can manage all of your owned and rented assets in one single location. The software makes it easy to locate, maintain, and track the utilization of equipment.

Atlas RFID from Jovix: Atlas RFID is an award-winning Material Readiness application from Jovix. Atlas RFID provides real-time visibility to all stakeholders throughout the supply chain. Employing a combination of web-based server software, mobile devices, and smart RFID tags and barcode labels, Atlas RFID removes impediments to productivity and ensures workers have the materials they need to spend more time on tools.

Milwaukee OneKey: As the industry’s largest tracking network, ONE-KEY streamlines everything from tool tracking to maintenance planning for Milwaukee tools and products. The solution includes asset ID tagging, equipment trackers, barcode scanning, and geofencing capabilities.

Linxup: Linxup helps you track data points for visibility into your fleet’s location in real time, driver and operator behavior, maintenance, electronic driver logs, and more. Its devices use vehicle power, solar power, or rechargeable batteries to tell you where your assets are, where they’re going, and how they’re getting there.

TruckIt: TruckIt is a dispatching and electronic ticketing cloud-based platform. The dispatch side gives insights into owned and rented assets for optimal utilization. Its ticketing system automates paper tickets, time sheets, billing, and payments. This data can then be used for material delivery verification, driver performance insights, project yield, and ticket reconciliation.

Enhance Equipment Management Processes

Construction equipment management will help you reduce downtime and delays. In the event that you do encounter some downtime, you can use your time effectively based on the information gathered through your management system. That may look like scheduling maintenance, moving equipment into storage, or swapping out parts. As you refine your system, you’ll discover ways to optimize the processes around construction equipment management.

For more insights into the construction industry, subscribe to our blog.

The post Guide to Construction Equipment Management: Everything You Need to Know appeared first on Digital Builder.

Did you miss our previous article…

https://www.arizonasolarsociety.com/?p=184

Leading Construction Teams are Increasingly Adopting Autodesk Build

Industry leaders such as APTIM, Barton Malow and Boldt are turning to Autodesk Construction Cloud’s project management and field execution solution to reduce risk, drive efficiencies and boost margins

San Francisco, Calif., July 27, 2021 – Autodesk, Inc. (NASDAQ: ADSK) today announced that Autodesk Build, the project management and field execution solution of Autodesk Construction Cloud, is now being used on over 8,000 active customer projects across the globe since being made available in February 2021. Construction teams are increasingly turning to Autodesk Build to bolster quality, safety and cost management workflows, and connect project data across the construction lifecycle in a single solution that is easy to deploy, adopt and use.

Contractors and owners adopting Autodesk Build to connect their project teams, data and workflows include:

- APTIM – an industrial construction, engineering and maintenance firm specializing in complex government, oil, gas, chemical and power projects

- Barton Malow – a general contractor building commercial, institutional and industrial projects across North America

- Boldt – a construction management firm building in the healthcare, industrial, commercial, food and beverage and renewable energy markets across the U.S.

- Burns & McDonnell – an engineering, construction and architecture firm working in the critical infrastructure sectors globally

- Polytek – a Belgian construction project management and engineering building complex projects for pharmaceutical and food sector clients

- Pond – an engineering, architecture, planning and construction firm serving defense, government, corporate and private sector clients worldwide

- Robson Communities – a residential developer creating master-planned active adult resort communities across the southwestern US region

Autodesk Build unifies best-in-class features from BIM 360 and PlanGrid with powerful new capabilities to deliver a cloud collaboration environment where information sharing and workflows are both tightly-controlled and highly-configurable. The solution features collaborative workspaces for project, cost, quality and safety management, as well as field collaboration and project closeout, and ties them all together in a common data environment.

With the project management features available in Autodesk Build and its PlanGrid Build app, which is purpose-built for mobile field collaboration, teams can organize and connect on RFIs, submittals, meeting minutes and predictive insights, staying ahead of any issues that could result in project risks. Using the cost management toolset, teams can enhance collaboration with project owners and suppliers by bringing them into the system to review contracts, change orders and payment applications securely, with confidence that any of their sensitive information will be safeguarded.

“Managing information across various technology systems can be counterproductive, leaving our teams and data siloed and ultimately resulting in increased rework, delays and risks,” said Werner Herbots, CEO of Polytek. “To deliver our projects with excellence, it’s essential that we have a powerful construction management platform to stay connected and coordinated. Autodesk Build empowers us to manage all aspects of a project from one single location so our workflows for RFIs, submittals, change orders and other critical processes are all tightly connected, and the team can easily collaborate and track progress.”

“Cost management in Autodesk Build creates transparency by gathering financial activities in a central location to easily track status and see how a change order is progressing and impacting budget,” said Emily Rech, program manager at Pond. “With Autodesk Build, we can remove information silos and drive accountability across project teams.”

Autodesk Build empowers stakeholders across construction teams to stay in sync, enhance collaboration capabilities, mitigate risks and enable data-driven decision making by focusing on:

- Single source of truth – Autodesk Build centralizes document management so teams can rely on a single source of truth for the latest project information and manage discussions around potential quality, safety, cost and schedule issues. Users only need one login and project administrators can control permissions for the various team members, trade partners and companies involved.

- Connected data and teams – Project stakeholders from multiple companies can connect in Autodesk Build for more efficient collaboration, ensuring everyone is in sync to minimize miscommunications and rework, and keep projects moving along schedule. With the ability to store all project data in one place and build integrations, teams can also connect their workflows throughout the lifecycle of a project, from design to operations.

- Predictive analytics and insights – Centralized data collection initiates a strong foundation for analytics across all workflows. Stakeholders can gain visibility into project- and operation-level insights that uncover risks, drive efficiencies and further boost profit margins.

“Bringing the entire project team together in Autodesk Build’s common data environment keeps everyone on the same page to minimize errors and the need for anyone to wonder, ‘Am I getting this right?” said Jim Lynch, senior vice president and general manager, Autodesk Construction Solutions. “Significant adoption for Autodesk Build in the five short months since it’s been available signals that teams across the industry are making strategic technology investments to maximize their ability to deliver high quality projects within budgets and timelines.”

About Autodesk

Autodesk makes software for people who make things. If you’ve ever driven a high-performance car, admired a towering skyscraper, used a smartphone, or watched a great film, chances are you’ve experienced what millions of Autodesk customers are doing with our software. Autodesk gives you the power to make anything. For more information visit autodesk.com or follow @autodesk.

Media Contact

Niyati Desai

Autodesk

[email protected]

Autodesk, the Autodesk logo, Autodesk Construction Cloud, BIM 360, and PlanGrid are registered trademarks or trademarks of Autodesk, Inc., and/or its subsidiaries and/or affiliates in the USA and/or other countries. All other brand names, product names or trademarks belong to their respective holders. Autodesk reserves the right to alter product and services offerings, and specifications and pricing at any time without notice, and is not responsible for typographical or graphical errors that may appear in this document.

© 2021 Autodesk, Inc. All rights reserved.

The post Leading Construction Teams are Increasingly Adopting Autodesk Build appeared first on Digital Builder.

How to Build Your Construction Tech Stack

Fact: technology and app usage is growing in the construction industry. According to the 2020 JBKnowledge ConTech Report, 22% of respondents indicated using six or more construction apps, up from 20.1% in 2019.

While the abundance of apps in construction is certainly a sign of progress (particularly with some reports that the industry is lagging in digital transformation), having lots of tools can be both a blessing and a curse.

Having too many choices when it comes to what tech to use can get overwhelming. It’s not easy to figure out which solutions to adopt, especially amidst growing teams and increasingly complex workflows.

Then there’s the challenge of ensuring that your technology decisions align with your high level business strategy and goals.

Finding and implementing the best construction tech is a tall order, but it’s something that you can accomplish if you take the time to build your construction technology stack — which is exactly what we’ll tackle in this post. The paragraphs below will shed light on actionable and expert-backed insights that can help you come up with the perfect tech stack for your company.

What is a Tech Stack?

A tech stack is a collection of apps and digital tools that are all used to serve a particular business function.

For example, sales teams or organizations can have a tech stack to facilitate the sales process. Teams could have an app for prospecting, another app for setting appointments, and a tool for tracking deals in the pipeline.

The same thing applies to construction professionals. There are apps that aid multiple components of a project, whether it’s design, estimating, building, or closing.

In some cases, the different tools in a tech stack can work together automatically (i.e. they’re integrated with each other or they’re all part of the same platform). Other times, apps are used in isolation and function as point solutions that simply address a specific area or need.

In today’s landscape, the former is infinitely better than the latter. Apps that are tightly integrated make data exchange between solutions much more seamless, allowing them to be interoperable.

This brings us to our next point…

What is Interoperability and Why Does It Matter?

Interoperability is the ability of computer programs to exchange information with each other. Interoperability is essential to a successful construction technology stack, because it makes it easier for you to access data and insights — so you can then put them to good use.

When you’re using a variety of construction applications, getting them to seamlessly integrate and share information will help you gain a better understanding of your projects, which leads to well-informed decisions.

Interoperability within construction apps also helps teams be more efficient. Nathan Wood, Chief Enabling Officer at SpectrumAEC, said it best:

“Interoperability means the ability for different project delivery stakeholders to effectively communicate and streamline information flow between one another, which is essential in the digital age of construction. Data insights will be hard to come by if you don’t first solve the interoperability dilemma. It’s about bearing down and investing the time necessary to build common language and optimize workflow, allowing teams to break down data silos and build them back better with the appropriate integrations and security protocols.”

How to Build Your Construction Tech Stack

Now that we’ve covered the fundamentals of technology stacks and why interoperability is important, let’s look at the steps you should take to successfully build a construction tech stack that works for you.

Create Your Strategy

The most important business decisions start at the top. Implementing technology throughout a company will be an uphill battle without 100% buy-in from the firm’s leaders.

As such, the company’s leadership team must be aligned behind a common goal and everyone should understand how technology can help the firm execute on its objectives.

What’s the role of tech in the overall business strategy? How much should be spent on the business’ tech stack and what’s the expected ROI? When those at the top have clear answers to these questions, it’s much easier to communicate and empower the rest of the organization to find and implement solutions.

Have the Right Team and Processes in Place

The term “people, process, and technology” is popular in the business world for a good reason: these three components must be closely linked to successfully execute in today’s modern environment.

Even the most powerful technology solutions will fall short without the right teams and processes.

So, consider having a dedicated team to oversee your technology strategy.

The construction firm Kraus-Anderson, for instance, set up the Business Technology Investment Committee (BTIC), a group that includes the company’s President, Head of IT, Head of Finance, EVP of Operations, General Council and President of Realty.

According to Tony Peleska, Kraus-Anderson’s VP and Head of Information Technology and Digital Transformation, the BTIC created a process “to review and monitor decision points for success.”

This process, says Tony, includes steps like conducting technology requests and self-assessments, developing a business case for the technology, and creating a comprehensive IT project plan.

This process allows the teams at Kraus-Anderson to not only evaluate and implement technology in the company, it also helps them track the technology’s performance and measure ROI.

See if you could adopt similar practices in your organization by assigning a team to oversee your tech stack and developing processes for technology requests and implementation.

Build the Right Foundation

The best way to achieve interoperability within your tech stack is to have various tools integrated with a connected construction platform.

Think of a connected construction platform as the foundation on which your tools, teams, and workflows can function. It connects all these components together and provides a common data environment, so information flows smoothly across the entire project lifecycle.

With a connected construction platform, people, processes, and technologies can stay aligned at all times, paving the way for higher levels of efficiency, smarter decisions, and ultimately better project results.

Identify Gaps and Needed Workflows

When deciding on what to include in your tech stack, it helps to identify gaps and redundancies that you can address with technology.

Start by listing out all the tools and processes that you’re using. From there, you’ll be able to surface gaps by finding the parts of your processes where tools don’t connect. For example, if there’s a step where you need to manually enter data from one app to the next, then you know that there’s an integration gap between the two solutions.

You may also find redundancies — instances where two apps are essentially accomplishing the same thing or are requiring you to complete unnecessary actions or tasks. For example, you could be sharing and storing duplicate documents in several places without a clear connection, when it’s more efficient to just have a single source of truth.

Look for Open APIs and Fine-Tune Integrations

At this stage, you may already have a platform in place. Pieces of your tech stack have started to come together, but you likely still rely on other niche applications to fill in the gaps.

When looking for components to add to your technology stack, set your sights on applications with open APIs or existing integrations with your current solutions. This will make it easier to connect the various software that you’re using, so you can get the most out of them.

As mentioned earlier, software integrations pave the way for data to automatically flow across your entire tech stack. This eliminates the need for manual entry, which reduces errors and data loss.

Bringing It All Together

As the construction industry continues to evolve and transform, having a solid tech stack will help you keep up and remain competitive.

To accomplish this, you need to start with a compelling high-level strategy and get buy-in from your organization’s leaders. It’s also helpful to have dedicated teams and processes around technology implementation.

Finally, it’s important to choose solutions that can function in a common data environment, so that your data, workflows, and teams can stay connected.

By taking these steps, you’ll be well on your way to creating a technology stack that serves your organization for years to come.

The post How to Build Your Construction Tech Stack appeared first on Digital Builder.

Did you miss our previous article…

https://www.arizonasolarsociety.com/?p=66

How to Connect Your Project Data with Business Intelligence

Construction teams are capturing more data than ever before. With the amount of activity happening daily on a jobsite, it’s easy to see how data can build up and become overwhelming to understand. According to FMI, 95% of the data generated by construction and engineering firms goes unused, which means we only have room to improve.

Teams don’t necessarily need more data; they need more insights that will help them leverage data more effectively in decision making. So, where do we start?

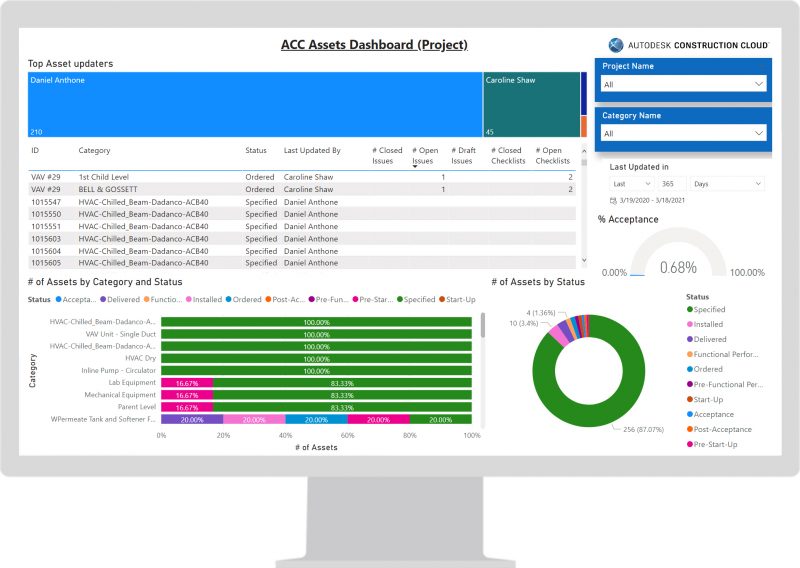

The first step is ensuring you have access to all of your project data and the right analytics tools to visualize further. The Autodesk Construction Cloud platform and BIM 360 has a great set of prediction and analytics capabilities built directly into the product. However, we know that many construction teams still rely on additional business intelligence tools, like Power BI or Tableau, in tandem with our technology to evaluate their company’s performance.

With Data Connector, teams can now quickly extract project data from the Autodesk Construction Cloud platform or BIM 360 for customized use in business intelligence tools, all through a single click. This saves teams time and money by giving them a built-in tool to extract data without needing expensive APIs or custom code. It also gives them the ability to improve data visualizations to make more informed business decisions.

Curious to see how Data Connector is being used by construction teams today? Let’s explore how Barton Malow has been utilizing Data Connector in their business operations.

Strengthening Technology Adoption

Ted Jennings, a Senior VDC Manager at Barton Malow, started using the data exported from the BIM 360 Data Connector to understand at an account level how various projects teams were onboarding as well as to look at the specific action’s users were taking within BIM 360. By understanding these trends, Jennings and his team were able to cultivate best practices and improve overall adoption of BIM 360 across all of their project teams.

“One big win we came away with after looking into our usage data was that we noticed a lot of people were wrongly assigning subcontractors roles,” said Jennings. “We realized that the existing role tagged as ‘Field Team’ was getting overlooked so by changing it to ‘Subcontractor’ teams began to more appropriately assign this role. This is one example of how a simple categorization mistake can lead to people not being given the right permission levels or access to the documents they really need.”

Understanding Project and Company Wide Performance

Evaluating project level performance has always been a critical part of any construction project, especially when it comes to looking at daily reports or analytics. However, cross project analysis is also an essential part of ensuring companies are getting a holistic view of how they are performing at an executive level. If you consider the amount of data generated from just a single project, you understand that looking at the data across tens of other projects is exponentially challenging to evaluate and compare.

Additionally, many teams are also using multiple software solutions, like ERP systems, financial applications, and other project management tools. So having the ability to aggregate all of their data into a single view is essential. This is a key reason many construction firms are turning to business intelligence tools that are made specifically to help visualize and compare larger amounts of data to help them understand what areas of their business need attention.

“It is critical for us to see a deeper level of cross project analytics and the Data Connector allows us to better understand project trends and commonalities so we can make decisions around how to mitigate those issues.” – Ted Jennings, Senior VDC Manager, Barton Malow

This was a key outcome Jennings wanted to achieve, as it was important for Barton Malow to use their business intelligence tools to evaluate their company performance across all of their projects. “It is critical for us to see a deeper level of cross project analytics and the Data Connector allows us to better understand project trends and commonalities so we can make decisions around how to mitigate those issues,” said Jennings.

Improving Project Quality

Although the Barton Malow team started leveraging Data Connector to help improve their onboarding and adoption, they are now focusing on diving even deeper into analyzing cross workflow trends to improve their project delivery. By evaluating things like RFIs, Submittals, and Issues across projects, Jennings and his team can now have a clear understanding of what actions need prioritizing and improve overall project success.

The other great thing about using the Data Connector is that any unique dashboard created within Power BI or Domo can also be viewed back within the Insight or Project Home modules in Autodesk Construction Cloud platform and BIM 360. This means that teams can leverage the powerful and customizable analytics features in business intelligence tools, but still have a centralized place to view all of their data.

Get Started with Data Connector Today

As more construction firms start adopting tools like the BIM 360 Data Connector to help leverage their data, teams will begin to see improvements in the way they do business. Whether that is better adoption of technology, streamlining project controls, or improving overall project quality, using data allows teams to learn and grow their business into the future.

Need help getting started with Data Connector?

Download our free Power BI template.

The post How to Connect Your Project Data with Business Intelligence appeared first on Digital Builder.

Did you miss our previous article…

https://www.arizonasolarsociety.com/?p=34