Home » Construction Blogs (Page 8)

Category Archives: Construction Blogs

Gaining Better Insights and Creating Greater Predictability on Projects Across Europe With Mercury Engineering

Mercury is a European contractor that builds and manages complex engineering projects that reimagine how people work and live in the built environment. Their determination and sharp focus enable project teams to deliver leading edge construction solutions across a range of key sectors, taking their clients to new territories including enterprise and hyperscale data centres, advanced technology, fire protection, technical support services, data centre facility management, healthcare and building services.

Mercury employs 6,500 staff, including subcontractors, currently working across over ten locations in Europe. With an overall turnover of £1 billion in 2020, Mercury invests heavily in learning and development for all employees. The company is focused on applying the best standards of health, safety, and governance throughout the organisation to support colleagues.

The team at Mercury focuses on delivering their clients vision through leading edge construction solutions. Pushing to go beyond their duty means Mercury turns clients into partners and builds strong relationships that thrive. Their digital construction journey began two years ago with the data centre sector of the business. As the company had grown, the team adopted lots of different technology solutions for their projects and they lacked a standardised approach to implement a connected construction journey. “Our company grew very quickly and added a number of projects to our portfolio. This meant that we began using several different platforms and methodologies across different projects and regions. It soon became obvious to us that a more standardised approach could improve our efficiencies and give us greater results,” reflects Aisling Goff, Business Unit Quality Manager for Mercury’s data centre business unit.

The business unit decided they would adopt one solution for all of their projects moving forward. The objective was to create a more unified and standardised approach to delivering projects for all of their clients. In the first instance, the team surveyed their employee groups to get an understanding of how technology could help them deliver better outcomes in their role. “We ran a series of surveys with our staff to get their feedback on all the different software they were currently using – asking them for the pros and cons in each case. We received input from colleagues in a range of roles, from engineers to document controllers,” says Aisling.

The road to standardisation

To further develop their technology roadmap, the data centre business unit team reviewed their project pipeline to evaluate incoming work and cost out their technology requirements accordingly. Ronnie Christie, Business Unit Manager, knew that using technology in a smarter way could better support the team to create continuity. Ronnie says: “We recognised that different sites within a division were reporting differently to the directors and their clients so a big ask of the technology solution we chose was something that could help us standardise our reporting mechanisms.”

When it came to choosing a technology solution, Mercury used Autodesk Construction Cloud’s BIM 360 platform for the first time four years ago on one of their data centre projects. The team initially used the solution for document control and generating snag lists on the project.

Aisling reflects: “When we used BIM 360 for the first time, we had to make sure the client was happy with the software and realised the benefit of using it.” After initially using the solution on one data centre project, Mercury then decided to use it on a new build project that spanned the entire construction phase. The team made use of more of the functionality available – such as workflows for daily reporting, commissioning, permits, check sheets as well as tracking labour and site numbers too. “When we used BIM 360 on our second data centre project, we were impressed with the additional functionality. It allowed us to create clearer workflows for RFIs and submittals alongside a whole range of project activities,” says Aisling.

Mandating for consistency

It was during this project that the Mercury team decided to mandate using BIM 360 on all projects in the future. “We knew that we’d need to approach our BIM 360 rollout to the business in a slow and structured way,” states Aisling. “We got the basics working really well on our first project, and it was only after this that we introduced more functionality to the team on the next project to ensure a smooth transition to the wider team.”

When it came to implementing the technology, the team ensured that employees were thoroughly supported through a comprehensive learning and development strategy. They ran training sessions for teams and individual employees and also created peer mentoring sessions for individuals to learn from each other, with the help of technology champions for the platform. The company also created standard operating procedures for using BIM 360, user guides and shared best practice through their internal skills hub.

“Our colleagues responded really well to the training and learning opportunities made available to them during the rollout stage,” says Ronnie. “For us, peer-to-peer training was key. Our business has expanded dramatically in the last few years due to growth across the unit and we have a really talented bunch of people with great expertise in using digital construction solutions. They were instrumental in strengthening the team’s understanding and use of BIM 360.”

Getting the most from the data to improve communication and collaboration

For Mercury, when it comes to integrating technology into their business, the team have focused on using the data they capture on projects in a richer way to develop better project insights. Aisling says: “We’ve integrated BIM 360 with Power BI to export data on quality, health and safety. We were unable to get this visibility before. Now we can draw greater insights from our projects to better manage risk, cost and quality.”

Better insights captured from project data can not only improve the construction process, but it can support the health of a business and improve the employee experience. “When new colleagues join and work with existing teams on different projects, they understand fully what processes they need to follow and what information we capture to measure our performance,” says Ronnie.

Collaborating across the supply chain happens within Autodesk Construction Cloud’s BIM 360 platform. “We now use BIM 360 to communicate formally with all of our project stakeholders,” says Aisling. “It’s where all project communication takes place and acts as a central source of truth for Mercury. Everyone uses BIM 360 – from a Quality Assurance team member or a Document Controller in the office to a supervisor using daily reports on site or a Project Manager overseeing daily activity.”

For me, the transparency [from BIM 360] has been transformative. Everything is real and things are no longer open for interpretation as project data is visible for everyone.—Aisling Goff, Mercury

Using one central source of truth in the form of a common data environment has enabled Mercury to empower their teams with full visibility of the status of all their projects. “All submittals and RFIs go through BIM 360 and our supply chain partners use the solution in the field to report on health, safety and quality. We also use the solution to manage our client teams; that can range from resolving questions that need clarification, verification, and design workflows. It works really well for us as we use the solution to manage up and down as well as across teams,” remarks Aisling. This has improved communication and collaboration between project stakeholders resulting in a dramatic reduction in the amount of miscommunication and lost documentation.

Setting the business up to succeed

For Aisling and Ronnie, the benefits of working more digitally are twofold – not only do their teams deliver a better client experience, but they are also able to ensure they are set up for success from the very beginning of a project. Ronnie says: “All of our projects are structured in the same way now using BIM 360. This means our colleagues can move between projects easily; they know what to expect when they join a new project team, and the business knows how to set itself up for success.”

Both Aisling and Ronnie agree that their favourite features enable them to use their data in a more meaningful way. Aisling remarks: “If I had to pull out my favourite thing about BIM 360, it would definitely be that it enables us to use the same parameters when it comes to analysing our data. This means we have a standardised way of reporting to use the data better.” For Ronnie, being able to benchmark across teams and see how they are progressing when audit reporting supports him in his role. Ronnie says: “I’m able to gauge how jobs are running in parallel with each other which has been really useful.”

Monitoring adoption has helped Mercury to establish where they need to put more focus. “As a company, we monitor what functionality each project is using in BIM 360 to make sure we’re getting the most out of the technology,” says Aisling. “Our data centre business unit has reached an average 90% KPI score for adoption. We’ve found that the last 10% of adoption in terms of maximising all the functionality usually involves brining all project stakeholders along and making sure they’re bought into the technology.” This also means Mercury can work collaboratively across their individual business units with their teams to share best practice, learnings and break down siloes.

“We now have much greater predictability and insights on our projects,” says Ronnie. Mercury has also fostered greater collaboration across their business units and wider company whilst standardising the data sets and data types they capture. “For me, the transparency has been transformative. Everything is real and things are no longer open for interpretation as project data is visible for everyone,” affirms Aisling.

Looking to the future, Mercury plans on ensuring all their teams across the entire company are getting the most from BIM 360 using the functionality available. In addition to this, working in collaboration with their clients, they are promoting the benefits of implementing standardisation and digital workflows within the AEC industry.

This year, Mercury is going through the process of gaining their ISO 19650 accreditation which highlights their ambition to fully utilise the international standards for managing information over the whole life cycle of a built asset using building information modelling (BIM). As a company, they are wholly committed to driving the digital agenda to create a more productive and efficient industry with better insights to deliver improved outcomes for clients and end users alike.

The post Gaining Better Insights and Creating Greater Predictability on Projects Across Europe With Mercury Engineering appeared first on Digital Builder.

Did you miss our previous article…

https://www.arizonasolarsociety.com/?p=410

Laing O’Rourke to float by 2024

Laing O’Rourke founder and chief executive Ray O’Rourke is planning to list the business on the stock exchange within the next three years.

O’Rourke revealed the timeline to take the country’s largest private contractor public in an interview with the Financial Times.

He said: “We will float the company in a few years’ time. By 2024 we will be in good shape.”

Latest results for the firm showed pre-tax profit jumped nearly 40% to £46m in the year to March 2020, despite revenue dipping 11% to £2.4bn.

Did you miss our previous article…

https://www.arizonasolarsociety.com/?p=405

Manchester considers net zero carbon new build by 2023

Manchester is being urged to adopt net-zero carbon for all new buildings when it introduces its new local plan in 2023.

A task group of private, public and third sector representatives brought together by the city council is urging the radical target for all building projects, without the use of carbon offsetting or a carbon tax.

All new development should also be required to deliver a significant reduction in embodied carbon in construction from 2023, with more stringent requirements introduced in future, recommends the Manchester Climate Change Partnership.

Contractor Laing O’Rourke, developers Muse, Bruntwood, Urban Splash and consultants Aecom, Arup, BDP, Buro Happold and WSP make up the high-level council task force.

The city council has cautiously welcomed the ambitious plan to make the city an exemplar for climate change action ahead of an autumn-winter consultation on the refreshed local plan.

Luthfur Rahman , Deputy Leader of Manchester City Council, said: “Manchester is committed to becoming a zero carbon city.

“The Partnership’s Roadmap, including the proposed Manchester New Build Standard, is a welcome contribution to the important discussion about how we will achieve this goal.

“The issue of climate change will be at the heart of the forthcoming refresh of Manchester’s Local Plan.

“We will look at how our planning and development system can support zero carbon objectives, and we will consider the Partnership’s proposals as part of this process.”

In the task force’s report it was acknowledged the viability of developments will be impacted by the building cost of achieving the Manchester Standard.

For net zero carbon in operation, this is estimated to increase by 4-6% for office developments and 8-10% for residential developments.

For the reductions proposed for 2023 in embodied carbon, this is estimated to be 20-30% across offices and residential assets.

Did you miss our previous article…

https://www.arizonasolarsociety.com/?p=398

Go-ahead deal for Manchester’s £90m Gallery Gardens

Developer De Trafford has finally struck a section 106 deal with Manchester City Council to clear the way for its Gallery Gardens residential scheme.

The 19 and 13 storey tower block scheme of 366 luxury flats was granted planning in March 2020 but both the council and developer had been wrangling over section 106 requirements.

Gallery Gardens Manchester has been designed by JM Architects

Under the deal, De Trafford will pay an initial £330,000 towards off-site affordable housing for the first phase of the development.

It was agreed after a viability assessment prepared by Eric Wright Construction and consultant Gleeds provided with a forensic breakdown of how much money it will take to deliver Gallery Gardens.

Construction costs were estimated at just over £62m for the first phase.

The project will be located in Castlefield between Hulme Hall Road and Ellesmere Street.

Did you miss our previous article…

https://www.arizonasolarsociety.com/?p=391

Ensuring the High Quality of Future Buildings by Accumulating Instantly Shareable Site Knowledge

この記事を日本語で読むには、こちらをクリックしてください。

Daiwa House Industry Co., Ltd. is developing a range of construction businesses, not only in single-family house building as seen in TV commercials, but also rental housing, commercial and distribution facilities, medical care, and nursing care facilities. Behind these promising developments is the enthusiasm of young employees and site managers, and the “Digital Construction Project” that supports them. For this issue, we interviewed Mr. Kazuaki Ishizawa, General Manager, Yokohama Branch, Kanto Construction Works Division of Daiwa House Industry, and Mr. Yoshinori Shimizu, who is working in Construction Works Department I in the same division. We asked them about the present and future utilization of PlanGrid

Construction Business that Leads Daiwa House Industry

Daiwa House Industry is diversifying its business, from construction to the management of single-family homes, condominiums, commercial and distribution facilities, hotels, and other areas. The Kanto Construction Works Division led by Mr. Kazuaki Ishizawa is in charge of commercial and business facilities, which means that it engages primarily in the construction of distribution facilities, stores, elderly care facilities, and hospitals. It is one of the leading divisions within Daiwa House Industry. The huge number of construction units underlies the strong performance of this division.

“As far as I know, when compared with other construction companies, our company constructs a huge number of buildings. I think one of the reasons for this is that our contract amount per building is more affordable than other companies. On the other hand, even while constructing a large number of buildings, we ensure that we are always able to deliver consistent quality to our clients.” (Mr. Ishizawa)

In order to consistently deliver high-quality buildings to our clients, it is certainly important that individual workers improve their skill levels through experience. However, from the perspective of the company as a whole, instead of depending on the technical capabilities of individuals, the company believes that the power of digital technology is important in terms of developing technical expertise.

Going forward, in order to continue our successful development as a company, organizational technological capabilities should be emphasized over individual technical abilities. —Mr. Kazuaki Ishizawa

“Going forward, in order to continue our successful development as a company, organizational technological capabilities should be emphasized over individual technical abilities. ‘Digital Construction Project’ started with this concept in mind under the direction of the President and CEO. The use of technology and the standardization of these techniques lie at the heart of this project.” (Mr. Ishizawa)

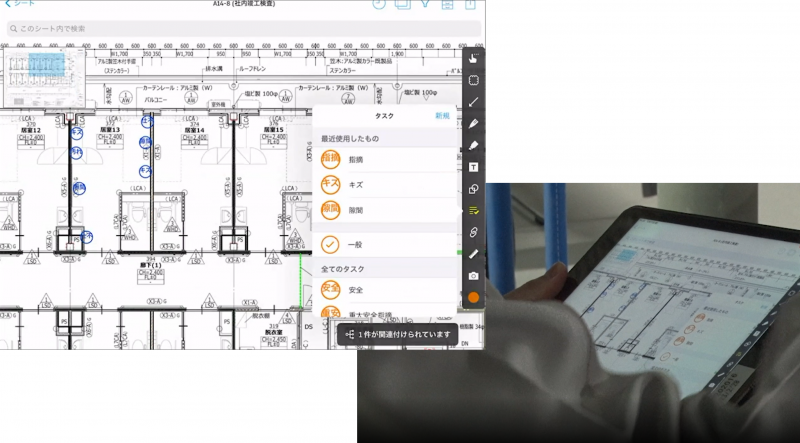

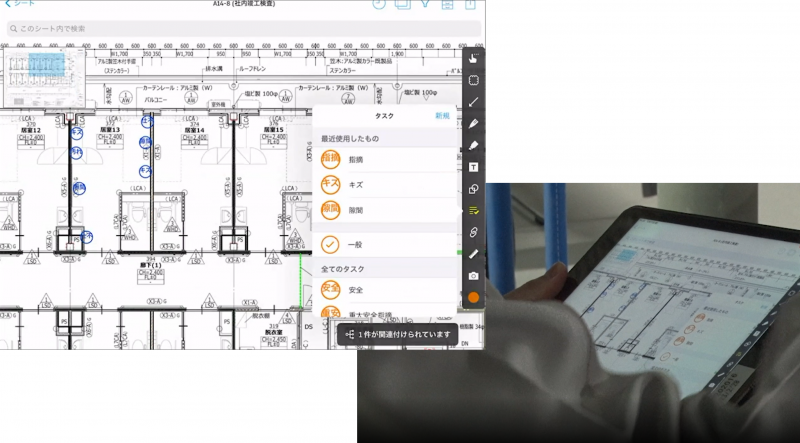

Autodesk, with whom Daiwa House Industry maintains a strategic partnership, introduced PlanGrid to Mr. Ishizawa, who was assigned as a project member, as one solution to promote the digitalization of construction sites. Mr. Ishizawa’s impression of PlanGrid was that it seemed to be “a very promising and deep solution.”

“PlanGrid enables us to inspect and check the site, store the site conditions, and immediately share and view the necessary information with all the concerned parties. Furthermore, it enables us to send necessary information to the people in charge both in and outside the company in a timely fashion. I immediately felt that these functions could be applied to a wide variety of jobs.” (Mr. Ishizawa)

Leading to the improvement of future building quality

Mr. Ishizawa initially thought about using PlanGrid to perform completion inspections, which are carried out before a building is handed over to the client. While learning more about PlanGrid, however, he realized that it might not only be useful for quality inspections of completed buildings, but also for overall quality checks, which include checking and recording site conditions obtained from safety inspections and patrols.

“Of course, such inspection operations are routinely conducted. However, each inspection operation has sheets in different formats and is conducted by different departments/sections. I thought that all of these differing formats and data collected by different departments/sections might be able to be coordinated in using PlanGrid.” (Mr. Ishizawa)

Mr. Ishizawa then instructed several members including Mr. Yoshinori Shimizu of the Kanto Construction Works Division to start initiatives for the practical utilization and the introduction of PlanGrid into sites in cooperation with Autodesk. Mr. Shimizu, who is working as site manager, says that he saw the immense potential of PlanGrid from the moment he was introduced to it.

“When using conventional paper documents, sharing information and decision-making took a long time. With PlanGrid, on the other hand, we can share information about the root causes of defects or other findings very easily and quickly if we have a tablet on a site.” (Mr. Shimizu)

When inputting data for the first time using PlanGrid, he realized that PlanGrid would help in on-site decision-making and improve work efficiency, and that it would possibly result in a substantial reduction of time and labor.

“The knowledge of the engineers working on their respective sites will be gathered and stored in PlanGrid, and by doing so, such data can be used effectively in the future.” (Mr. Shimizu)

By utilizing PlanGrid in practice, Mr. Shimizu realized a number of other advantages. He noticed its “usability” at construction sites where people are extremely busy.

“For example, without going to all the trouble of preparing an inspection sheet, the preparations for inspections and safety/site patrols can be completed by inserting a single drawing into PlanGrid. I only need to visit the site and input the site information and photos in the stamps that are on PlanGrid. I do not need to go to the trouble of returning to my office to compile the sheet, and I can finish the work on site. Photos taken on your smart phone can be uploaded immediately. Just by placing the photos in their proper positions on the drawing, there is no longer any needs to send an e-mail to someone else. All the project members can share this information immediately.” (Mr. Shimizu)

Through the introduction of PlanGrid, workers can easily find whether a task has already been finished or is still in progress simply by checking the stamp. They can uniformly manage tasks such as site patrols and safety checks, which would normally require a number of different people to visit the site. Furthermore, there is no need to visit the site; instead, they can check the tasks from the office, meaning that work efficiency will dramatically increase, which will also lead to a drastic improvement in the quality of construction.

“The fact that we can share findings, technical information and prevent problems in advance is significant. This will lead to improvements not only in near-term performance but also in future building quality, which today’s young employees will provide.” (Mr. Shimizu)

Utilization of PlanGrid is an investment in the future

The range of uses of PlanGrid is continually expanding. At present, PlanGrid is being promoted for use not only in safety patrols and a variety of inspections, but also for use during pre-construction site investigations.

“Before a site manager is assigned, a supervisor conducts a site investigation. The supervisor investigates the access of vehicles, the conditions of neighboring buildings and surrounding fences, and the infrastructure. I had the idea that PlanGrid might also be useful during such investigations, and therefore, I asked Shimizu to customize PlanGrid so that not only site managers but also supervisors would be able to use it effectively. Preparations for this application of PlanGrid have already begun.” (Mr. Ishizawa)

At present, Mr. Shimizu is heading up the widening use of PlanGrid, and the number of PlanGrid users is continually increasing. However, Mr. Ishizawa is not satisfied with the current state. Mr. Ishizawa hopes for a time when everyone on site will be able to use PlanGrid and will continue steady efforts toward that goal.

“At present, all the members who have a relatively high level of technological knowledge are tackling how to utilize PlanGrid; however, enabling this technology to reach all employees is our next challenge. I think it is necessary that this technology be used by a larger number of workers.” (Mr. Ishizawa)

By gathering and storing the knowledge of different people [in PlanGrid], younger or less experienced site managers can refer to this information easily by searching for a keyword, allowing them to deal with problems quickly on-site. —Mr. Yoshinori Shimizu

According to Mr. Ishizawa, he set a target for the branch offices he manages in Kanagawa, Chiba and Ibaraki Prefectures and made at least two people in each office use PlanGrid on-site. They also have opportunities to share opinions with other members.

“If members who use PlanGrid on the site steadily continue to share their experience with other members, the use of this technology will spread quickly across the company. I am currently working with Autodesk to promote the general use of PlanGrid across the company.” (Mr. Ishizawa)

Mr. Shimizu says that customization (preparation) will be essential to develop the use of PlanGrid horizontally across construction sites.

“We will thoroughly customize PlanGrid so that it will become very simple to use. At first, we will try to reach a level where everyone feels that ‘a job can be completed using only the tools on hand’. By gathering and storing the knowledge of different people, younger or less experienced site managers can refer to this information easily by searching for a keyword, allowing them to deal with problems quickly on-site. Used in this way, the value of PlanGrid will be easily understood by the workers on-site.” (Mr. Shimizu)

Mr. Ishizawa says that he thinks that the utilization of PlanGrid is an investment for the future.

“Up until now, the output differs depending on the person in charge, and this has been covered by the whole staff to maintain a consistent level of quality. Going forward, I am sure that by continuing to accumulate data in the cloud, integrating that data and drawing on it as information, we will definitely be able to increase not only quality stability, but further increase the quality level of staff.” (Mr. Ishizawa)

On the other hand, while Mr. Ishizawa admitted that there are concerns about the future role of technical skills in the construction industry, he says that balancing technology and human skills is the key to moving forward.

“The technical skills that are learned by sweating over your work on-site and by sharing experiences with other skilled construction workers are also very important, because we work with people. We may be able to create a good product using digital technologies, however, we cannot establish a trusting relationship without skilled construction workers. I think that only our people who worked on sites while using digital technology are in the end able to communicate accurately with skilled construction workers. While teaching PlanGrid is important, we should not neglect other kinds of teaching. I do not believe that the Japanese construction industry will completely change in the next five to ten years. However, I hope that the generation following Shimizu will be able to work more easily and enjoyably, while at the same time carrying out consistently high-quality work for our clients. I am engaging in this challenge with considering such thoughts.” (Mr. Ishizawa)

⠀

⠀

瞬時に共有可能な現場の知見を蓄積することで、まだ見ぬ未来の建物の品質を担保する

TVコマーシャルでおなじみの戸建住宅のみならず、賃貸住宅や商業施設・物流施設、医療・介護施設など、多様な建築事業を展開する大和ハウス工業。その好調の裏には、若手・現場所長たちの情熱と、それを下支えする「デジタル・コンストラクション・プロジェクト」の存在がありました。今回は同社横浜支社関東工事部統括部長である石澤一晃氏と同部工事第一部で活躍する清水慶典氏にインタビュー。PlanGrid活用の現在と未来についてうかがいました。

大和ハウス工業を牽引する建築事業

戸建住宅や分譲マンション、商業・物流施設、ホテルなどの建設から運営まで事業の多角化を進める大和ハウス工業。石澤一晃氏が率いる関東工事部は、商業施設部門・事業施設部門、すなわち物流施設や店舗、高齢者施設などのビルの建設を手掛ける部門。現在の大和ハウス工業を牽引する事業部門のひとつです。その好調要因を支えているのが、圧倒的な建設戸数だといいます。

「恐らくどの建設会社と比べても、圧倒的な棟数を建設しています。他社に比べて1棟あたりの受注金額が安価であるという点が理由の一つとしてあげられると思いますが、裏を返せば棟数をこなしつつ、いつでも安定した品質をお客様に提供するための努力を重ねているということでもあります」(石澤氏)。

安定的に高品質な建物をお客様に提供するためには、個人が経験を積んでレベルを上げることが重要だという意見もあるのは確か。しかし会社全体として考えると、個人が持っている技術力に頼るのではなく、デジタルの力を重要な技術力のひとつとして捉えたといいます。

「むしろこれからは、会社として成功や発展を続けるために、個人の技術力よりも組織的な技術力の方が重要視されるべきです。そうした考えの元、社長の肝煎りでスタートしたのが『デジタル・コンストラクション・プロジェクト』です。テクノロジーの力を活用して技術を標準化するという考えが根底にあります」(石澤氏)。

そのプロジェクト・メンバーとしてアサインされた石澤氏は、会社として戦略的パートナーシップを結んでいるAutodeskから、施工現場のデジタル化を推進するソリューションの一つとしてPlanGridの紹介を受けました。“とても未来のある、奥の深いソリューション”という印象を受けたといいます。

「現地を確認・チェックして、その状態を保存する、それを関係者全員ですぐに必要な情報を共有して見ることができる。さらには、タイムリーに社外や社内の担当者に必要な情報を発信できるという一連の機能が、様々な業務で応用できると直感的に感じました」(石澤氏)。

将来の建物の品質向上にも繋がっている

当初はPlanGridを、お客様に引き渡す前に実施する竣工検査に活用しようと考えていた石澤氏。ところが説明を聞いているうちに、完成した建物の品質検査もさることながら、安全の検査やパトロールなど、現場を確認し、記録を残すという、もっと大きな意味でのクオリティチェックに活用できるのではないかという発想になったといいます。

「もちろん、従来もそういった点検業務は実施されていました。しかし、各々の作業によってフォーマットが異なる帳票があり、担当部署も違う。今までは部署ごとにバラバラだった帳票やデータを、PlanGridを用いることで連携させていくができるのではないかと思います」(石澤氏)。

そこで石澤氏は、同じく関東工事部のメンバーである清水慶典氏を含む数人のメンバーに指示。Autodeskと共に、実用化、および現場浸透に向けての取り組みを開始。現場所長として活躍する清水氏は、PlanGridに出会った瞬間から、その可能性を感じ取ったといいます。

「従来の紙の帳票による運用では、担当者が持っている情報の共有や意思決定が決してスピーディーには行われてはいませんでした。ところがPlanGridであれば、現場にタブレットさえあれば非常に簡単に、しかも即時で、不具合の根本原因や指摘事項などの情報共有が可能となります」(清水氏)

初めてPlanGridを使って入力した時点で、現場における意思決定の一助となり、業務効率が上がる。時間や労力の大幅な削減に繋がる可能性があると実感したといいます。

「そして何よりも、それぞれの現場で活躍する技術者たちが持つ知見をPlanGridに集約し、蓄積することで、今後、そうしたデータを未来に活かすことができるのではないかと感じました」(清水氏)

実際に活用してみると、さらに様々なメリットを実感したという清水氏。多忙を極める現場の最前線における“使い勝手の良さ”に注目します。

「例えば、帳票をわざわざ作らなくても、PlanGridに図面を1枚入れれば、それで検査や安全、現場巡視の準備は終了します。現場に赴き、PlanGrid上に存在するスタンプに現地情報や写真などを入れてしまえば、わざわざ事務所に戻って帳票をまとめることもなく、その場で作業を終えることができます。写真もスマートフォンで撮影してすぐにアップロードが可能で、図面の場所に写真を置くだけで、誰かにメールで送る必要もなく、瞬時にプロジェクト・メンバーで情報共有が可能です」(清水氏)

PlanGridを導入することで、その作業が終了しているのか、継続しているのかが、スタンプひとつで見極めることが可能に。現場巡視や安全確認など、従来は複数の担当者が現場に足を運んでいた作業が、PlanGridを介して一元管理できるようになりました。しかもそれが現場に行かなくても、事務所で確認することができるため、業務効率は格段にアップ。それは工事の品質にも大きな影響を及ぼしているといいます。

「やはり、これまでの指摘事項や技術情報を共有し、事前に回避できるようになった点は大きいと思います。それは目先の成果だけでなく、現在の若年層が担っていく、将来の建物の品質向上にも間違いなく繋がっていくと思います」(清水氏)

PlanGridの活用は未来への投資

PlanGridの活用アイデアはさらに広がりを見せています。現在は、安全パトロールや様々な検査においてはもちろん、工事を実施する前段階の現地調査においても活用を進めています。

「現場所長が配属される前段階において、管理職による現場調査が行われます。車の乗り入れや隣の建物、周りの塀の状況やインフラなどの調査をしますが、それもPlanGridでできるのではないかと考えました。ですから、現場管理者だけでなく管理職も使いこなせるようカスタマイズしてほしいと、清水に依頼して運用準備を始めているところです」(石澤氏)

現在は、清水氏を中心に普及活動が進められ、PlanGridを活用する人員が増えつつある状況ですが、石澤氏は満足していません。石澤氏が目指すのは、現場の誰もがPlanGridを活用できる世界、そのために地道な取り組みを続けていくといいます。

「今はテクノロジーに対する知識レベルが比較的高いメンバーが取り組んでいますが、現場の担当者全員に普及したときにどうなるのかというのは、これからの課題です。まずはより多くの人財にこのテクノロジーに触れてもらうことが必要だと思っています」(石澤氏)

石澤氏が管掌する神奈川県、千葉県、茨城県の各事業所には目標を設定し、事業所内で必ず最低2人にPlanGridを実際に現場で使ってもらい、意見を共有する機会を持っているといいます。

「チャレンジしたメンバーが他のメンバーに広めていくという活動を地道に続けていけば、やがて会社全体に浸透していきます。そこは現在、Autodesk様と一緒になって考えながら進めている段階です」(石澤氏)

現場に水平展開するためには、カスタマイズ(下準備)が必須だと清水氏は言います。

「とにかく簡単に使えるよう徹底的にカスタマイズしていきます。まずは“そこにあるものを使うだけで、簡単にできる”と誰もが感じるようなレベルに持っていきます。色々な人の知識を収集し蓄積することで、若い現場管理者や経験の少ない現場管理者が、そのキーワードを選ぶだけで指摘事項を閲覧。現場ですぐに対処ができるようになれば、目に見える効果として、その価値を現場に理解してもらえるようになると思います」(清水氏)

そして石澤氏は、PlanGridの活用は未来への投資だと考えているといいます。

「これまでは、担当者によってアウトプットの違いがあり、それを皆でカバーして品質を保ってきました。これからは、クラウドにデータを蓄積し、繋ぎ、情報として引き出すということをくり返すことによって品質の安定化、いや品質が安定するとともに、担当者のレベルが高くなることは間違いありません」(石澤氏)

その一方で、“建設業界の技術力は本当にそれでいいのか”という懸念もあるというが、テクノロジーとヒューマニズムの両立がカギになるといいます。

「現場で汗水たらして建設技能労働者と様々なことを共有しながら身に付ける技術力もとても重要です。なぜなら、私たちは人と仕事をしています。デジタルで良品は作れるかもしれませんが、建設技能労働者たちとの信頼を作ることはできません。デジタルを駆使しながら現場でたたき上げられた人間こそが、結局、建設技能労働者とのコミュニケーションも正確に取れるのだと思います。PlanGridの指導も重要ですが、それ以外の指導もおろそかにできません。5年~10年という期間で日本の建設業が180度様変わりするとは思っていませんが、いずれ清水の後輩たちが楽になる、楽しく仕事をしながらお客様に価値を提供できるようになると期待しながら、今は取り組んでいます」(石澤氏)

The post Ensuring the High Quality of Future Buildings by Accumulating Instantly Shareable Site Knowledge appeared first on Digital Builder.

Top 10 Construction Companies in the U.S.

How the Biggest Construction Companies in the U.S. Are Building Our Cities & Workforce

As the U.S. works to bounce back from the pandemic, top construction companies are helping lead the way to recovery. Across the industry, you can feel the momentum in resilience, creativity, and the human spirit for problem-solving.

While spending has seen fluctuation lately, it’s expected to rise over the next several years. In fact, according to the U.S. Census Bureau, national construction spending is expected to exceed $1.55 trillion in 2021. That’s a 7.5% increase from 2020. Of that $1.55 trillion, $1.2 trillion is expected to go to the private sector, with much of the remaining funds addressing public needs. With the passing of a major Infrastructure Deal, official construction spending estimates may change. The deal is expected to generate about two million jobs per year, for the next ten years, with an emphasis on America’s physical infrastructure.

So, who are the largest construction companies leading the way? We’ve created a SlideShare of the top 10 construction companies in the U.S. to answer that exact question. Our list is composed of companies ranking on ENR’s Top 400 Contractors list. On the SlideShare you’ll find information about each company’s location, revenue, employees and year founded. Flip through below, then continue reading to discover insights about how a few of these top companies, and more, tackle some of the most common construction challenges.

10 of the Largest Construction Firms in the U.S.

Here are the top 10 construction companies in the United States as listed above in our SlideShare.

1. The Turner Corp

- Location: New York, NY

- Employees: 10,000

- Revenue: $11.77 billion

- Founded: 1902

2. Bechtel

- Location: Reston, VA

- Employees: 55,000

- Revenue: $17.6 billion

- Founded: 1906

3. Fluor

- Location: Irving, TX

- Employees: 53,000

- Revenue: $19.166 billion

- Founded: 1912

4. Kiewit Corp

- Location: Omaha, NE

- Employees: 22,000

- Revenue: $10.3 billion

- Founded: 1884

5. The Whiting-Turner Contractin Co

- Location: Baltimore, MD

- Employees: 3,800

- Revenue: $6.2 billion

- Founded: 1909

6. Sto Building Group Inc

- Location: New York, NY

- Employees: 2,200

- Revenue: $4.9 billion

- Founded: 1971

7. Tutor Perini Corp

- Location: Sylmar, CA

- Employees: 10,000

- Revenue: $4.76 billion

- Founded: 1894

8. AECOM

- Location: Los Angeles, CA

- Employees: 54,000

- Revenue: $13.24 billion

- Founded: 1990

9. Skanska USA

- Location: New York, NY

- Employees: 7,600

- Revenue: $6.5 billion

- Founded: 1971

10. DPR Construction

- Location: Redwood City, CA

- Employees: 5,900

- Revenue: $5.94 billion

- Founded: 1990

How Top Construction Companies Approach 3 Common Challenges

Of course, with opportunity comes new obstacles. If you’re adept in problem solving, the following obstacles are exciting challenges that can give you a competitive edge if tactfully approached. For a better understanding of how you can approach three very common challenges in construction, we’ve provided examples of how top firms have succeeded in solving these problems.

1. Complex projects with tight deadlines

As technology improves, expectations rise as well. Highly technical projects require significant resource planning, forecasting, and attention to detail. Add in tight turnaround times and the obstacles only increase. Gilbane Building Company, ranked #11 on 2021’s ENR400, is one of the construction companies tackling challenges like this one head-on.

The Rhode Island-based firm constructed a state-of-the-art engineering lab and academic facility for students at the Wentworth Institute of Technology (WIT) in downtown Boston, Massachusetts. This project was WIT’s first new academic building in over 40 years.

Gilbane was brought in to construct the new four-story, 78,000-square-foot academic building for engineering innovation and sciences. They were on a short, 15-month schedule. In order to meet the tight turnaround and represent the polytechnic university’s focus on innovation, the firm leaned on cutting-edge technologies and processes. Specifically, Gilbane leveraged prefabrication, design-assisted preconstruction processes, and virtual reality (VR) to meet the deadline and high-tech requirements.

Speaking to prefabrication as one of those crucial pieces to finishing on time, John Myers, Gilbane’s director of visual design and construction for New England says, “Off-site fabrication for us, from a safety standpoint, from a schedule standpoint, from the standpoint of being able to do things in parallel instead of in sequence, those are the things that make Gilbane successful.” For a deeper dive on this this impressive, yet challenging project, we recommend you read the full story here.

In the spirit of higher education, Gilbane also created a “living” classroom out of the project. It allowed WIT students to learn the most current and advanced construction methods as Gilbane went through the building process. Students got hands-on experience with each step of the project in real-time.

2. Identifying benefits of new technology in preconstruction

We’ve all heard the adage: “No one likes change.” It’s common for firms to face resistance to new technology and innovations. Usually, the resistance is not due to an individual’s resistance—it’s an organizational challenge. Improving structure and processes can be slow when the productivity and profit gains haven’t been fully understood by decision-makers. The truth is that technology proves to be an ally over and over again. We look at how two leading firms responded to different scenarios related to the need for new technology in preconstruction.

2a. Proving value of new technology with money saved

Multinational construction and development company, Skanska, ranked #9 on the 2021 ENR400, encountered some pushback from clients when moving from 2D to 3D modeling. The company decided to switch to 3D modeling for quantity takeoff to save time and money on projects.

The Skanska team has found that the best way to reassure hesitant clients is to provide proof of 3D modeling’s value. Kelsey Stein, National Preconstruction Technology Manager at Skanska explains, “By having better standards that we can give to the design team, it’s helped us perform a closer estimation while saving time and money on our projects.”

The 3D takeoff uncovered missing quantities that accounted for a 28% discrepancy….saving a tremendous amount of money that would have been lost under the traditional 2D method.

To provide greater context for clients, Skanska compared the results of a traditional 2D takeoff and a 3D takeoff using Assemble on the same project. The 3D takeoff uncovered missing quantities that accounted for a 28% discrepancy in the curtain wall scope. As a result, the firm saved a tremendous amount of money that would have been lost under the traditional 2D method.

2b. Building easy-to-use technology for your own employees

PCL, a construction company coming in at #14 on the 2021 ENR400, found themselves needing to create easy-to-use technology for their preconstruction managers—so they did just that.

Breaking out the challenge, PCL’s estimators and managers were adept at reviewing 2D drawings and managing the preconstruction process. However, the review of 2D drawings can be a very manual process and slow down workflows. This created inefficiencies. On top of that, preconstruction managers were regularly receiving more 3D models from the design team as they moved to digitizing their workflows.

Knowing they had to improve access to insights that 2D drawings couldn’t provide without significant effort, PCL created a multidisciplinary team to evaluate and identify their priority project KPIs. They determined which ones would be most effective at tracking design progress in real time and got to work building their own data management and interpretation tools.

“Predictability is the name of the game when it comes to construction. If we can better track the progress of design, then there will be little-to-no surprises when we receive milestone design deliverables.” -Nick Kurth, PCL Construction Enterprises Inc.

Their team can now easily access critical, real time project progress data through Autodesk Assemble, Autodesk Revit and a Power BI dashboard. This technology enables them to better interpret data and generate cost-effective designs with the most efficient use of materials.

Nick Kurth, VDC Manager at PCL Construction Enterprises Inc, shares why the dashboard was so critical, “Predictability is the name of the game when it comes to construction. If we can better track the progress of design, then there will be little-to-no surprises when we receive milestone design deliverables. This dashboard solution is another means for us to drive lean principles around target value design. It’s also essential to have transparency between our design team and our precon team, and that’s a key part of what this provides.”

3. Having geometric & cost certainty

As a Fortune 500 firm and ranked #8 on the 2021 ENR400, AECOM is used to partnering with clients in the public and private sectors to solve complex construction challenges. The premier infrastructure firm is known for its construction and design-build approach, which leads to optimized collaboration, productivity, and efficiency. Under the design-build construction delivery model, contractors, designers, and owners collaborate as a team to meet owner expectations.

AECOM America’s BIM Director, Russ Dalton, is responsible for helping the teams behind the firm’s construction and design-build approach win new business. He then supports them in making sure the projects are executed effectively.

Technology is essential for helping Russ do just that. His team, and AECOM as a firm, has embraced BIM 360 to achieve geometric certainty and cost certainty. They’re now moving toward operational certainty. Through their commitment to achieving certainty, and the technology that enables it, AECOM has carved out a competitive advantage.

“We’ve witnessed a 32% increase in productivity with this methodology.” -Russ Dalton, AECOM America

AECOM’s Barclays Center Arena project was a testament to the effectiveness of how they use BIM 360. Russ shares, “We looked at [this project] through predictable lenses to make sure that in the construction process it could be completed with geometric certainty and cost certainty.”

The $450 million project was not only finished early but came in under budget due to AECOM’s commitment to BIM 360. Russ says that the use of BIM 360 generated “$4.5 million in cost savings” on the project. He goes on to add, “We’ve witnessed a 32% increase in productivity with this methodology.”

The Road Ahead

These leading construction companies are showing the industry, and the nation, what’s possible on the road ahead. They’re also highlighting that it takes innovation, persistence, and the right tools to not only survive, but thrive in the face of challenge. Remember, obstacles are opportunities and the best days are ahead for our industry. Technology is helping us get there.

The post Top 10 Construction Companies in the U.S. appeared first on Digital Builder.

9 Ways to Maximize Jobsite Productivity

Productivity is simply the measurement of the effectiveness of effort. The rate of productivity is measured as total output per unit of input. In construction, an example of output would be something like the square footage of flooring installed or cubic yards of earth excavated with the input typically being measured in man-hours.

![]()

Did you miss our previous article…

https://www.arizonasolarsociety.com/?p=288

Goodbye, Spreadsheets: Win More Work with Centralized Bid Management

As the world continues to open back up, we’re starting to see more signs of recovery in the construction industry. Research from Dodge Data & Analytics and Autodesk shows that bidding activity has been increasing since the start of the year. In fact, bidding activity in BuildingConnected was up 36% in January 2021, compared to a three-month pre-pandemic average.

This is great news overall, and as a contractor, you can capitalize on these opportunities by optimizing your systems to keep up with the increasing number of bids coming your way.

The best way to do that is to eliminate cumbersome tools like spreadsheets.

Spreadsheets are useful for tracking basic information but they’re not ideal for higher level processes and tasks such as bid management.

Since the bidding process requires you to manually enter and track numerous bits of info, putting everything in a spreadsheet can get messy and confusing. This could lead to missed bids and loss of potential work.

What’s more, collaboration can be a pain with spreadsheets. You can’t share files in a centralized manner, so people typically end up emailing each other different versions of the file, resulting in issues with version history and conflict between updates.

Another problem with using spreadsheets? It’s much more difficult to analyze data. While they can display raw information in neat rows and columns, extracting useful insights from spreadsheets is largely a manual process.

All this to say that spreadsheets aren’t great for managing bids and they’re certainly not going to help you win more work.

If you’re still using spreadsheets, it’s high time to replace them with a centralized bidding management system. The right solution can streamline the bidding process and make collaboration easier, ultimately helping you win more bids.

Our recent guide discusses how a centralized bid management system can benefit subcontractors. Download it for free.

DOWNLOAD EBOOK

Read on to explore some of the key insights you’ll find in the guide.

What is a Centralized Bid Management System?

A centralized bid management system refers to a single platform on which you can centrally manage the entire bidding process. It’s an excellent solution for contractors, because it enables you to track and handle all your bids from one place, which can help you increase your win rates and revenues.

Case in point: Bowman Flooring Contractor, a Georgia-based specialty contractor increased its win rate by 25% and revenue by $9 million when the company adopted a new bid management system.

The team at Bowman used to rely on Excel and emails to manage bids, and they decided to implement bid management technology to improve their processes.

In doing so, Bowman was able to be more organized and keep all the necessary bidding information in one place. The new software made it easy for teams to track and assign bids and they were able to prioritize jobs that were more likely to win. What’s more, they could pull up past project estimates, which led to better estimates on current projects.

“Our new software totally changed the way we do business,” said Mike Adams, Senior Project Manager at Bowman Flooring Contractor.

Benefits of a Centralized Bid Management System

We’ve discussed the general benefits of a centralized bid management system, now let’s take a look at the specific advantages of having one.

Streamlined Bid Management

Having a centralized system that’s accessible to multiple team members reduces the need for double entry and other manual tasks. Unlike using spreadsheets, which involves manually entering data, a centralized system for bid management lets everyone work on the same information at any given time.

As a result, subcontractors can minimize errors, confusion, and tedious work like reviewing and re-entering data.

Easy Bid Tracking

Juggling multiple bids can be a nightmare when you’re using spreadsheets and other manual methods. These cumbersome tools can’t centrally store data, so it’s easy for information to slip through the cracks.

When you have a centralized bid management system, you can easily get a bird’s eye view of the entire bid process. You’ll also have a single source of truth when it comes to the status of all your bids and invites, so you’ll never miss an opportunity again.

Better Collaboration

A centralized bid management system allows teams to work together without a hitch. Since information is stored and accessed in the cloud, team members can collaborate in real-time and everyone can always get their hands on the most updated information. This eliminates confusion and miscommunication, which leads to a smoother bid management process.

Simplified Bid Solicitation

A centralized bid management system also improves the process of bidding on and bidding out. When soliciting bids from other subcontractors, the information they submit feeds directly into the bid, so there’s no need to re-enter the same info.

Having the ability to manage both bids in and bids out from a centralized platform paves the way for more competitive final bids. You can track proposals in one place and make data-driven decisions before submitting your bid.

Download Our Free Ebook

To win more bids in today’s increasingly competitive market, you need all the help you can get. A centralized bid management system enables you to stay organized, save time, and understand your bids better, so you can win more projects and continue to grow.

Download our free ebook to learn how a centralized bid management system can help you improve your business.

The post Goodbye, Spreadsheets: Win More Work with Centralized Bid Management appeared first on Digital Builder.

Did you miss our previous article…

https://www.arizonasolarsociety.com/?p=263

World’s largest scaffold wrap installed at Bullring

The final section of the world’s largest scaffold banner covering the temporary scaffolding at the iconic Selfridges department store in Birmingham has now been installed.

The striking dogtooth flower design wrap measures almost 9,000 sq mts – 58% bigger than the currently recognised Guinness World Record holder for the largest scaffold banner which was installed in Madrid back in 2018.

The giant wrap is 246 metres long and 37 metres high – equivalent to a giant wall of nineteen double-decker buses stacked eight high.

The team from specialist Embrace Building Wraps started installation work at the end of last year.

In total the team installed 5,888 linear metres of scaffold tubes for the banner frames, vertical curved shaping, and buffer rails. If laid end to end the scaffold tubes would extend around four miles.

The weight of the printed wraps alone is just under five tonnes. Embrace seamlessly joined 24 individual banners of various shapes & sizes of which 85% had three or more adjoining perimeter edges that had to line up perfectly with the adjacent banners.

Installation of the frames and digitally printed wrap will disguise renovation work by BAM on the store.

The banner features an artwork design produced by Birmingham-born designer Osman Yousefzada comprising of interlocking six metre diameter dog tooth flower designs in three contrasting colours.

Greg Forster, Managing Director at Embrace Building Wraps said: “If you have ever tried lining up wallpaper then this is supersized to another level as the average dimensions of each individual banner are 388 m2.

“Our dynamic Operations Team had their work cut out for them and have really delivered on this industry-leading project which has been a fantastic team effort between ourselves, BAM Construction and the Midland Scaffolding Services Teams on site.”

Cleveland Bridge administrators to resume production

Administrators for failed steelwork contractor Cleaveland Bridge UK this week are calling some of the 200-strong workforce back to work to restart production for committed projects.

Insolvency partners at FRP have marketed the business for sale and confirmed they have opened talks with several interested parties.

After discussions with the bridge builder’s existing clients with live projects, the administrators intend to restart production this week, subject to the formal agreement of terms with customers and finalisation of insurance arrangements.

Required staff will be contacted this week, while the remainder will continue to be furloughed as part of the Coronavirus Jobs Retention Scheme.

Martyn Pullin, partner at FRP, said: “We are looking to restart production and continue to hold discussions with interested parties over the future of the business.

“We are working quickly and diligently to assess the viability of those approaches and will need to determine how they align with our objectives and duties as Joint Administrators.”

Did you miss our previous article…

https://www.arizonasolarsociety.com/?p=210