Manage Changes, Don’t Let Them Manage You

Nowadays, it’s not uncommon to be inundated with information highlighting the importance of collaboration and communication in design and construction projects. Naturally, most teams, if not all, have the goal of being proficient in these areas given that it’s key to successful outcomes and maintaining profit margin. However, it is also common for architecture and engineering, as well as general contracting firms, to struggle with precise and timely communication of changes.

An uncommunicated change in the design phase can cause several weeks’ delay resulting in thousands of dollars wasted. The further along the change goes unrecognized the greater the impact with potential outcome leading to stop construction for redesign, and on average of 35% of all construction projects will have a major change, according to Project Analysis Group. To help eliminate these challenges, it is recommended to implement change management. Effective change management enables better coordination leading to less risk in design, and improved quality in construction.

Change management with the Change Analysis tool

The Design Collaboration module in Autodesk BIM Collaborate offers the Change Analysis tool, which enables users to understand the design changes incurred on their projects. Teams can establish watch groups to closely monitor changes, configurable based on user criteria.

For example, a user can select watch groups for teams, models, or objects. Once a watch group is configured, the Change Analysis tool will share notifications automatically to the group about any changes impacting assets relevant to the group. Effectively making it easier to keep up with designs in continually evolving projects.

Change Analysis tool and watch groups in action

So, how does this show up in the real world? Here are a couple of cases studies where the Change Analysis tool and watch groups could have helped prevent negative outcomes.

Scenario #1: Design Phase

Consider an architect working on the design of the façade in a new building. The structural engineer on the same project decided to change the floor slabs, reducing them from 20 to 10cm from the façade edge because less space was needed for rebar.

This change looked pretty similar in the plan, but now the designed facade is 15cm distance from the slab causing a 5cm gap. The design team is using Design Collaboration to share information, but because there was no change management or watch group established, the change was missed when sharing the models with the greater team.

Eventually, when plans went to the main contractor, they realize the problem between the slab and the façade, but it’s too late. As a result, the design had to be updated leading to a 2-week delay.

If change management was implemented in this scenario, when the structural engineer’s new BIM Model was uploaded in Design Collaboration with the new slabs (and new dimensions), the architect would have automatically received a notification that something has changed, since the architect created a slab watch group. This change notification would have prompted the architect to go back to the design, and adapt the façade line to meet the new slabs design. Now, when the information is sent to the main contractor, the design is of much greater value because it’s inclusive of changes—which, in turn, reduces or eliminates delays.

Scenario #2: Preconstruction

Similar to the design phase, change management is equally important to the preconstruction phase. Consider a client went for a site walk, and requested a change to add a door to the facilities room. The architect made the change, and communicated it to the blockwork subcontractor to add the door on site. The architect also updated the drawings, but did not communicate the change to the broader team.

As a result, during model coordination the blockwork in the facilities room was set up as “frozen design”, and the services team were given the green light to start the manufacturing drawings. Because the architect did not communicate the change to the broader team there was no clash, and coordination ultimately missed this change.

This miss required a change order to be made for the design to be redone. New materials had to be ordered to site, and the removal and reinstallation had to be done delaying the project; costing time and money.

How could this negative outcome have been avoided?

In this scenario, it would have been recommended for the services team to create a watch group with the blockwork; let’s say they named the group “Blockwork Frozen”.

While the services team were working in the design, a notification would have appeared in Design Collaboration of a new model from blockwork with a change in the specific area that was “frozen”. The services team could have then requested more information from the blockwork subcontractor and client before going into manufacturing and installation. This approach would have resulted in no delay or unforeseen costs.

New features for change management

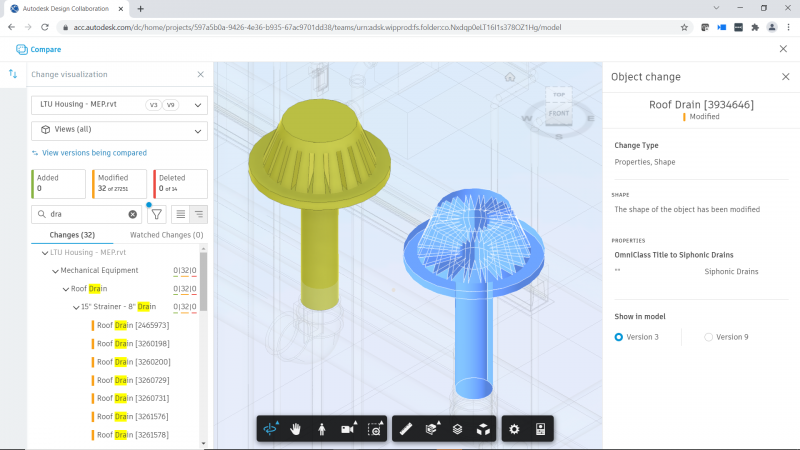

As depicted in the earlier case studies, it is imperative to establish a strategy for change management. The Change Dashboard in the Change Analysis tool provides users with a single view pane where they can see the changes as well as dive into details about those changes—giving immediately useful insight and flexibility in design. To further improve the Change Analysis tool, Autodesk just released a few new features:

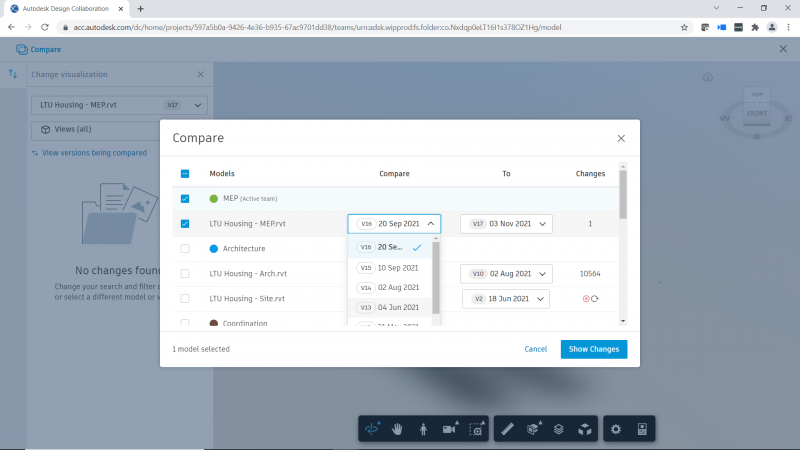

Comparison of non-consecutive versions allows users to compare any two design versions of a project against one another. This benefit being the ability to track scope change, understand decisions made, and reference outdated designs. This gives the team more power to easily track how a project changes over time.

New viewer experience permits users more control on the comparison workflows and transparency in the selections of models for the viewer. It also offers flexibility to see changes by discipline with the object tree and flexibility to see changes with multiple attributes selected.

Filter improvements have been made to enable users to more easily see different changes by project attributes as well as provide a better experience overall when filtering. Users can now filter by discipline, modification type, and category. Users can also take advantage of the search function that permits filtering based on names of specific objects.

With the Change Analysis tool and these new features, users can now take even more control of the outcome of their projects, de-risk deadlines, and reduce waste. Considering from 2012 to 2015, just 25% of projects came within 10% of their original deadlines, having a tool that helps to mitigate unforeseen delays is critical.

During design and construction of buildings, making changes is an inevitable part of the process. The Change Analysis tool in Autodesk BIM Collaborate has been defined and designed to help users make sense and stay on top of all changes. It makes it easy to find and identify changes with automatic notifications, and the user interface improvements make it more intuitive for users to compare versions. Reach out today for a demo.

The post Manage Changes, Don’t Let Them Manage You appeared first on Digital Builder.

Did you miss our previous article…

https://www.arizonasolarsociety.com/?p=1298

Key Takeaways from Construction Cost Management Report by Dodge

Cost management is key to ensuring construction projects stay on budget and on schedule. Yet many projects, as many as 33% come in over budget, as reported in the Construction Cost Management Report by Dodge Data & Analytics (Dodge). Surveyed contractors note that even among their best-performing projects, one out of five does not meet the budget requirements.

Efficiently tracking construction costs and monitoring risks make a big difference in maintaining budgets. Tracking costs and monitoring risks, however, requires a strong cost management discipline. Insights into current cost management practices can help fine-tune practices to build discipline. In this article, we’ll review highlights from the report and key takeaways to drive your cost management discipline.

Key takeaways

- Owners and general contractors alike prefer a single primary tool for cost management, complimented by a limited number of third-party tools.

- Forecasting costs with real-time field data is the top future need for cost management.

- Alignment between owners and general contractors is critical to building an integrated cost management discipline, and revealed as an opportunity for both project teams and solution providers.

- Project-focused staff shows higher capability of being involved in cost management on a more holistic level. One reason is due to the ease in which technology allows this to happen.

Owners and contractors prefer a single cost management tool, yet most use more than one

Overall, owners, general contractors, and specialty contractors use more than one tool for cost management. Forty-four percent leverage more than one tool but lean on one as their primary. Thirty-three percent use two to five tools with none as their primary. Only 21% use one tool alone, while 5% use more than five tools with none as their primary.

For respondents in project-related roles, there is a strong preference for using a primary technology tool for cost-management-related challenges such as establishing a system of cost accounts, status reporting during a project, and identifying areas of the project that require more attention in real-time.

For best results from a primary cost management tool, prioritize ease of access and use.

We can see a consistent preference for having a primary cost management tool, yet just over a fourth of owners and contractors actually use one tool alone. The leading approach to construction cost management relies on a primary tool with supporting tools. For that reason, it’s important to choose a primary tool that allows you to connect your project data to cost activities and schedules. Integrations factor in here too to connect the field and office teams while avoiding data silos.

For best results from a primary cost management tool, prioritize ease of access and use. These solutions should connect to schedule and cost activities over the lifecycle of the project.

The Dodge report also indicates a preference for third-party tools among respondents. About 47% use third-party tools, with around 60% leaning on desktop applications and 40% using cloud-accessible ones. Thirty-two percent of owners and contractors use internally developed tools, and 16% use spreadsheets.

We’ll likely see the number of people using internally developed tools and spreadsheets decrease in the future due to the customization capabilities of third-party tools and the maintenance costs of homegrown solutions. Organizations can generate better cost-related outcomes for all involved partners by focusing on using fewer, more comprehensive tools that engage all stakeholders in a shared approach to cost management.

Success criteria for cost management solutions: what owners and general contractors expect

When measuring cost management success, respondents indicated that they use the following three metrics most frequently:

- Turnaround time on processing change orders/variations

- Achieving expected profit margin

- Final cost compared to budgeted cost

Owners and contractors are split evenly on the subject of spending levels on cost management. Thirty-nine percent believe they are spending more than they should have to, 32% think they are spending the right amount, and 29% say they’re spending less than they should. In the subgroups, variation exists with owners more likely to believe they’re spending too much, especially those in public entities (55%). Contractors, on the other hand, especially those in trades, are the least likely to believe they are overspending (31%).

There is also a significant amount of variation between how owners and general contractors measure the success of cost management solutions. Owners cite the following metrics most frequently:

- Final cost compared to budgeted cost (30%)

- Generating useful data to benchmark for future projects (26%)

In comparison, contractors pinpoint minimal unplanned changes as their top success criteria. These preferences align with the responsibilities of each role but also indicate a lack of synergy on what successful cost management means.

Forecasting costs with real-time field data in top future need for cost management

Respondents selected the most critical future need from 14 cost management practices. Thirty percent selected forecasting critical costs with real-time field data as the most important to improve over the next three to five years. This practice ranked number one across all four regions studied, with the United Kingdom selecting it most frequently (32%) and Canada choosing it least frequently (26%).

Other top future needs were dynamically tracking each dollar in budgets (29% overall) and managing collaborative workflows (26% overall). As with other areas surveyed, we can see variance between the subgroups. Owners are most interested in dynamically tracking budgets and using field data for forecasting. These are two cost management practices that are also beneficial to contractors.

Three times as many contractors (compared to owners) want to improve their future estimates. Twice as many want to benchmark cost performance. Again, these two practices are beneficial to owners yet appear to be more pressing needs for contractors.

Project teams could be more involved in cost management

One area of opportunity for construction firms is the greater involvement of project teams in cost management. The report emphasizes the ability of these teams to participate in an integrated approach to cost management. Dodge’s findings “indicate that project-focused staff are ready and able to participate in a more holistic and integrated approach instead of the traditional office-based function with just discrete, periodic inputs from the field.” This was made evident by project-based staff reporting:

- Higher levels of cost management capabilities

- Lower levels of difficulty with their most challenging cost management activities

- Greater satisfaction using technology to address them

These responses indicate a significant opportunity to improve cost management practices by involving capable, skilled staff in the process. Doing so will help to integrate the practice into a firm-wide discipline.

Owners and contractors have opportunity to align more

In the Dodge report, there are notable differences in priorities for owners and general contractors. For example, contractors note improving cash flow as a top need. Yet owners are more focused on improving their ability to forecast critical costs with real-time data from the field. Both of these areas require involvement from owners and general contractors. For example, cost flow contributes to the owner’s overall project health, and forecasting critical costs requires contractor participation.

Variations like the one mentioned above represent a need for greater owner and general contractor alignment. Getting on the same page about cost management success, tools, and priorities will power leaner construction and smoother workflows throughout all phases of a project.

From cost management insight to action

To move cost management forward, owners, contractors, and project staff need a comprehensive tool they can rely on to centralize and improve the visibility of related cost activities and risks. This tool should be equipped with capabilities to support the future top need of forecasting costs in the field with real-time data.

We understand how important an integrated, collaborative cost management discipline is to the health and success of your projects. If you’d like to see Autodesk Construction Cloud’s cost management offering, please contact us for a demo. We’d love to show you around.

The post Key Takeaways from Construction Cost Management Report by Dodge appeared first on Digital Builder.